Challenged by new climate change rules, maritime shipping seeks inspiration in upgrading the past, while boating’s future is charged with lightning…

Maritime transport is the backbone of world trade, carrying some 80% of international trade in goods, producing approximately 3% of global greenhouse gas emissions - more than aviation. The eventual cost of reaching net-zero in this sector is expected to be between $2tn and $3tn, $2billion of which would be needed by the UK’s maritime sector.

Fuelled by the continued expansion of international trade, the volume of goods shipped by sea is projected to triple by 2050. Under a business-as-usual scenario, shipping’s climate footprint could increase by as much as 250% by mid-century.

Special measures

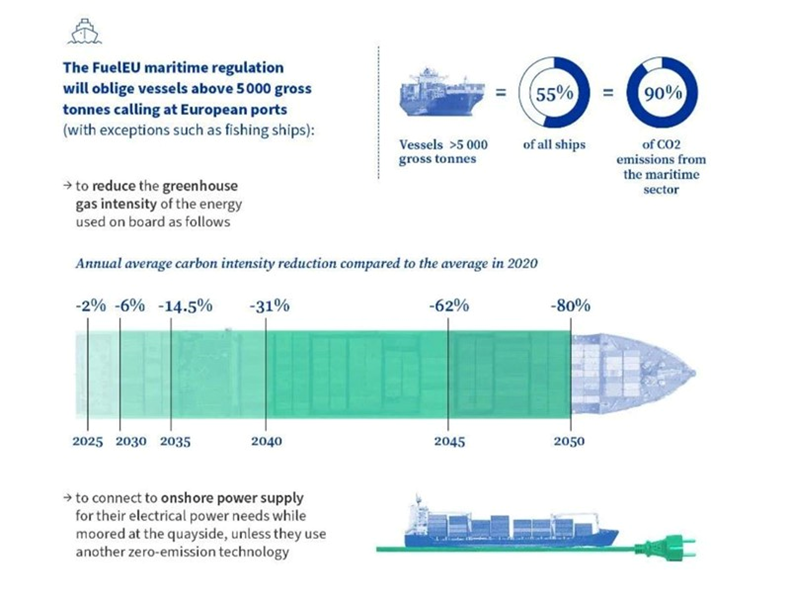

To encourage the use of renewable and low-carbon fuels within shipping and reduce its carbon emissions, the European Union (EU) has recently agreed new rules for climate-neutral shipping and adopted the FuelEU Maritime initiative.

Shipping is thought to be a ‘hard-to-abate’ sector because of the prohibitive cost of meaningfully reducing emissions, while the technologies are not yet widely available. Under the new agreement, shipping will be covered by the EU’s emissions trading system (ETS) from 2024 and FuelEU Maritime from 2025. The regulation demands the greenhouse gas intensity of maritime fuels be reduced by 2 per cent in 2025 and 80 per cent by 2050.

Credit: EU green fuel requirements / European Council

The new law will establish an incentive scheme to promote renewable fuels of non-biological origin with excellent prospects of decarbonisation. Fossil fuels will be excluded from the regulation’s certification process. From 2030, both passenger and container ships will be required to use an onshore power supply for all electricity needs while moored at major EU ports.

Hybrid measures could cut ships’ emissions now

There are two important considerations when thinking about decarbonising maritime transport. One is how emissions are cut in the short term; days, months, years. These would involve solutions such as limiting the speed at which ships travel (‘slow steaming’), operational measures, retrofitted wind propulsion and using shore power. These can be applied to existing vessels. The second is what is done over decades, which means a change in fuels.

Cutting fuel consumption

Slow steaming shows the greatest potential. Slowing ships down has a huge impact on fuel consumption, while retrofitting them with wind-assisted technologies such as the Flettner rotor and technology to optimise routes, will allow for an even greater cut in fuel consumption.

Shore power would allow ships to plug into renewable electricity to power operations when they are in port. In turn, it also motivates ports to become smart energy hubs while creating opportunities for more hybrid battery vessels on short sea routes.

Uncertainty, the fuel of the future

There is no single preferred candidate, yet, for the best choice of zero-carbon fuel, Methanol is one potential, ammonia is another. It could just as easily be multiple fuels that are selected for future use. It could be that tankers are fuelled by ammonia, while ferries will be battery powered.

Back to the future

Shipping is notoriously difficult to decarbonise, and zero-carbon technologies that can be applied at scale to large ocean-going ships do not yet exist. However, one way of removing carbon from ships is to return to wind power, albeit without the need for canvass.

Mitsubishi’s Pyxis Ocean, chartered by Cargill, is the first vessel to be retrofitted with two WindWings, large wing sails measuring up to 37.5m in height, to be fitted to the ship’s deck to catch the power of the wind.

This modern, steel and fibreglass version of sails, developed by the UK’s BAR Technologies, (built by the Norwegian Yara Maritime Technologies) could produce an average fuel saving of 30% on new vessels – a saving that can be higher if used in combination with alternative fuels. Wind is zero-emissions, renewable and predictable – something that offers efficiencies gains in operating costs.

On an average global route, each WindWing can save 1.5 tonnes of fuel per day with greater savings possible on trans-ocean routes. While this will reduce a carbon footprint, it translates into significant savings on fuel costs for ship operators.

The installation of the wings took place at a Chinese shipyard and the vessel is now conducting her maiden voyage.

The WindWings project, co-funded by the EU, could help the industry meet carbon reduction targets by offering a retrofit solution to decarbonise existing vessels. This is particularly attractive given that 55% of the world’s larger ships are up to nine years old.

BAR Technologies plans to build hundreds of wings over the next four years. The company describes wind as a cost-free fuel that provides a substantial opportunity to reduce emissions and operating costs.

Flying on a blue dream

Elsewhere, it is possible to see a very different approach to decarbonising boats, albeit this time in the leisure boat sector. Electric boats are not a new idea, but concern over climate change has driven a surge in interest. The Swedish company Candela went back to basics to completely redesign the powerboat.

Candela’s boats are not prototypes, they are in production and on the water around the world. The company’s story began in 2014, when founder and CEO Gustav Hasselskog realised his 28ft power boat (8.5m, but boats are measured in feet) used 15 times more fuel than a car to travel equivalent distances. Much of that fuel is used to push the hull through water, a medium 700 times more resistive than air.

Huge energy-efficiency gains can be made by lifting the hull out of the water on hydrofoils to free the boat from drag, something Hasselskog and his team of engineers set out to do. These ‘flying boats’ consume 80% less energy than conventional boats and are up to 90% less expensive to run.

Super reduced carbon, super reduced costs

A 100km journey that would cost €250 in fuel in a 28ft, conventional internal combustion engine-powered boat now costs €20 with a charged battery. As Hasselskog says a hydrofoil catamaran design was chosen because of its advantages over conventional electric boat designs. It reduces water friction by a massive 80%, consumes 80% less energy with 80% less resistance.

Thanks to this technology, Candela claims its P-12 Shuttle uses 80% less energy than conventional vessels.

The first production day-cruiser model was released in 2019, with the latest, the C-8, launched in January 2023. Essentially, Candela has come up with an entirely new class of boat. Beside a redesigned hull, the hydrofoils are also novel, being controlled by a group of in-house designed sensors.

A wing beneath the waves

Six height sensors around the hull point downwards from the bow, and out in front of the boat, to create a constantly updated 3D image of the waves and sea surface. The gathered data is combined with signals from the boat’s IMU (an inertial measurement unit with a gyro and accelerometer) and a GPS signal. This data is fed to the boat’s flight controller (an onboard computer that calculates the optimal angle of attack and twist of the hydrofoil surfaces) to perfectly balance the boat as it moves through the water. This controls the roll of the boat in a manner similar to the way flaps and ailerons work on an aircraft wing. Except here, the whole ‘wing’ is twisted 100 times a second, something the designer calls active stabilisation. It‘s the product of five years of development, assisted by calculating the fluid dynamics in a University of Barcelona supercomputer simulator.

Raised on hydrofoils, the hull is actively stabilised so it does not slam into any waves. The propulsion pod is completely submerged, with no powerful outboard engines revving and belching gasoline fumes, so the ride is silent, and, it appears, free from seasickness.

Road going batteries

These sleek flying boats are powered by batteries and charging systems from Swedish luxury electric car designer Polestar. High-capacity automotive batteries are more cost-effective than sourcing from niche suppliers of marine batteries, which previously prevented electric boats from competing with their fossil-fuelled counterparts.

Candela’s engineers have developed a revolutionary electric-powered propulsion mechanism. Each component of the C-POD has been designed for maximum efficiency and low drag. The direct-drive electric pod motor has no gears, no need for oil changes and no energy loss. This produces a 99.55% transmission efficiency powering the contra-rotating propellers, developing enough power to make a 28ft, 1,750kg boat, plus eight passengers, ‘fly’ at 30 knots. Candela claims this is the most efficient boat motor ever built. The pod itself is tiny, with a diameter of 10.5cm. It uses 75kW on take-off, settling down to a steady 50kW when the boat hull is up and flying on its hydrofoil. A similar-sized combustion boat uses around 600kW to achieve the same speed.

Servicing needs and costs are cut substantially. A standard commercial outboard requires an annual at a cost of a €1,000 or so regardless of the number of hours in use. In comparison, the pod-driven E-boat system has a drivetrain that can go for 3,000 hours of operation without intervention. Because it is a direct-drive system, there is no gear box or transmission, no oil changes, no filters, and no cooling system, because the heat this generates is conducted away from the shell into the water. The only checks needed are on exposed wiring, which can be protected with regular cleaning after use.

Could the ubiquity of fossil fuels have made us complacent on pushing the boundaries of technology?

What other technologies do you think could both help cut Shipping’s carbon emissions while reducing costs and improving efficiency?

Why not throw in your thoughts in the comments right now? Log into your EngX account and jump straight in (or register for EngX here)