Redefining Robotics Through Specialisation

The robotics sector is undergoing a quiet revolution. After years of fascination with humanoid robots and general-purpose systems, the industry is now embracing a more grounded, function-first approach. In 2025, the rise of task-specific robots is changing how robotics is designed, financed, and deployed—offering a powerful alternative to complexity without sacrificing innovation.

Rather than attempting to mimic the full range of human actions, task-specific robots focus on doing one thing—but doing it exceptionally well. Whether it is transporting goods across factory floors, delivering supplies in hospitals, or inspecting infrastructure in hard-to-reach environments, these machines are reshaping the landscape of automation.

Technology That Serves Purpose

Recent developments in edge computing and embedded AI—such as NVIDIA’s Orin NX platform—are enabling real-time decision-making without the need for cloud dependency. This shift allows robots to work reliably in the field, with increased autonomy and reduced latency. The hardware is smaller, the systems more power-efficient, and the applications more scalable.

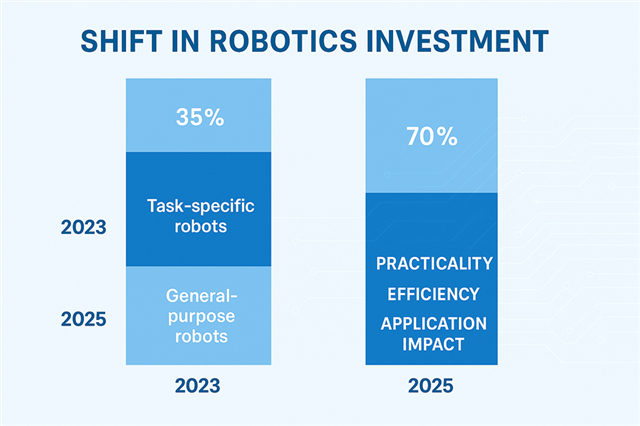

This technological maturity has coincided with a shift in investor priorities. More than 70% of robotics venture capital in early 2025 was directed at companies building specialist, commercially deployable platforms, not general-purpose humanoids.

It is a telling indicator of where the real value lies.

Real-World Impact: From Hospitals to Industry

Consider the case of Ati Motors in India. Their autonomous electric vehicles are streamlining internal logistics for major manufacturing firms. Likewise, Diligent Robotics in the United States is transforming healthcare workflows with ‘Moxi’—a hospital robot that handles routine deliveries, reducing pressure on nursing staff.

These are not speculative technologies. They are already operating in live environments, solving problems and returning value to stakeholders. They prove that practical design and technological discipline can outpace flashier, less targeted ambitions.

Implications for the IET Community

For members of the IET and the Robotics and Mechatronics Technical Network, this shift represents a significant opportunity. We are seeing a move towards engineering for application—where success is measured not by the novelty of the form factor, but by the impact of the solution.

As researchers, practitioners, and educators, we are called to adapt. This may involve realigning curriculum content, redirecting research efforts, or fostering deeper collaboration between academia and industry. It also means preparing for the human–machine partnerships that these robots will bring—through skills development, user-centric design, and inclusive deployment strategies.

Looking Ahead: Building a Function-Driven Future

Task-specific robots are not a compromise; they are a response to real-world needs. They represent the next chapter in intelligent automation—one that favours purpose, precision, and integration over spectacle.

As the Robotics and Mechatronics TN continues its mission to inspire, connect, and support our members, we encourage you to share your own experiences with function-focused robotics. Join our upcoming webinars, contribute to our discussions on EngX, and help us chart a course toward a future that is not only automated, but meaningful.

Have a comment, experience, or case study to share? Let us know below or start a conversation in the Robotics and Mechatronics Community on EngX.

For questions or collaboration, email us at RoboticsTPN@ietvolunteer.org