On this day in (engineering) history…

To build her, money is not a problem. At 46,000 tons and measuring 882 feet in length, she is 50% heavier and 100 feet longer than anything else afloat. Sacrificing speed for luxury, she is the biggest ship of her line and will be the largest and grandest of her time. She uses 29 boilers – 24 double ended Scotch class boilers and five single ended boilers – all set in six boiler rooms - to produce 46,000 horsepower and contains three million hand driven rivets. And it has taken 25 tons of grease and soap to launch the 26,000-ton hull, watched by 100,000 people.

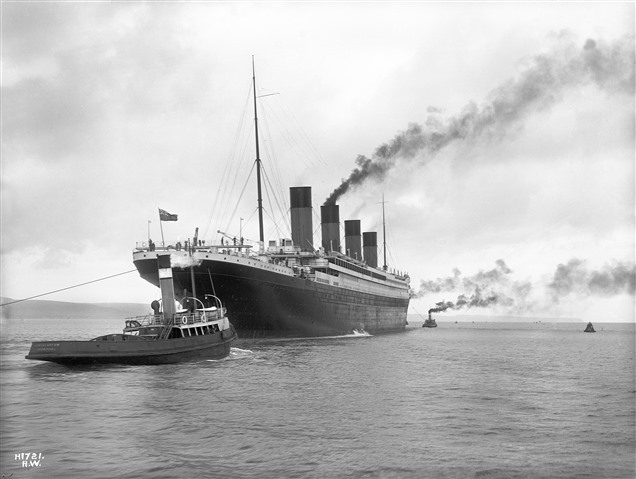

Today, April 2, 1912, Titanic undergoes sea trials at Belfast Lough.

A mythical ship

Titanic, and her sister ships Olympic and Britannic, were commissioned by the White Star Line as a riposte to Cunard’s Lusitania and Mauretania, then two of the fastest liners on the Atlantic route to New York. Titanic was commissioned in 1907 to boost White Star’s Southampton – Cherbourg – New York route, by being the biggest, most luxurious ship on the ocean. Even the propellers would be placed far enough apart to prevent vibration and noise disturbing the paying passengers.

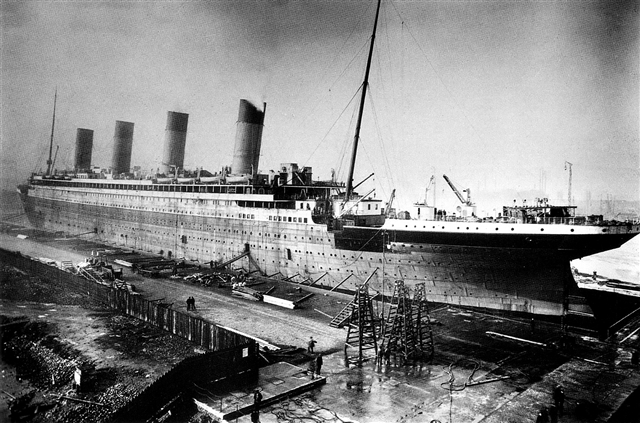

Building her was a herculean effort. Harland and Wolff were given a free hand to spend as much money as they liked, including a 5% profit. Even so, Titanic still went over budget, which meant removing some extra luxury features, including electric lifts and swimming pools.

Titanic under construction, fitting out, 1911 Source: Wikimedia Commons

The yard didn’t have the facilities to build such a gigantic ship. Harland’s installed two new slipways and added two gantries with moveable cranes and lifts. To lift the boilers, the yard pulled in a 200-ton floating crane. It took 15,000 workers to build her side-by-side with Olympic. Both ships cost £3 million (£310 million today) to construct.

When she was launched, a White Star employee is supposed to have said, ‘even God himself could not sink this ship.’ And on the face of it, that nameless individual would have been right. Titanic had sixteen watertight compartments in the lower section, with remotely operated, watertight doors.

Her reputation for safety was both second-to-none and tragically misplaced.

Satisfactory sea trials

At 6AM, on April 2, two days after fitting out was completed, Titanic left Belfast to begin her sea trials, carrying 78 stokers, greasers and firemen, with 41 crewmembers. Joining them were Edward Wilding and Thomas Andrews, Harland and Wolff’s chief architect. Also present were Harold A. Sanderson of the White Star Line’s parent company, the International Mercantile Marine Co. (IMM); radio operators Jack Phillips and Harold Bride were there to fine-tune the Marconi radio equipment, while Francis Carruthers represented the Board of Trade (which regulated shipping in the UK).

The trials, which took place on Belfast Lough and in the Irish Sea, consisted of driving Titanic at different speeds, testing her turning ability and performing a crash stop – where her engines were run from full ahead to full astern. It took 3 minutes and 15 seconds to stop the ship, over a distance of 850 yards. She sailed 80 nautical miles (90 miles) at an average speed of 18 knots (21 mph) and a maximum of a little under 21 knots (24 mph).

Titanic returned to Belfast at 7PM that night, and an hour later left for Southampton, where she arrived at midnight on April 4. She was towed to Berth 44 to await preparations for the maiden voyage, due to begin on April 10.

Why?

Since the night it sank, there have been questions about what caused the disaster. The ship was running at or close to full speed, as was practice at the time. Slowing it down and avoiding the berg was not easy, and the hull would have struck the ice at a relatively high speed. That iceberg strike caused damage over 100 metres on the starboard side of the ship, piercing six of the 16 watertight compartments. Those watertight compartments placed across the breadth of the ship were not watertight. They were sealed only horizontally, but not vertically. The tops were open and the walls didn’t extend far enough above the waterline. As the onrushing water overtopped the top of each bulkhead, the ship was pulled further under the water. Sealing them with watertight roofing would have reduced interior passenger space, making the ship less comfortable.

While the vessel had a double bottom (two steel skins along the bottom of the ship, it lacked a double hull, something that could have reduced the damage from the iceberg impact.

Engineering reasons why

In 1991, the Imax expedition to the wreck site picked up small chunks of metal, one inch thick, each with three rivet holes. Charpy testing (where a steel specimen is held against a backing and struck by a 30kg pendulum on a 0.74-metre-long arm. The contact is noted and the forces recorded electronically, millisecond by millisecond) on a small piece of one of the pieces of Titanic steel proved the metal to be highly brittle.

This brittleness is caused by two factors. One is cold temperatures, it was cold that night in the North Atlantic. Another factor is high sulphur content of the steel. A third factor is a high impact load.

Upon examination, the Titanic steel was found to contain high levels of oxygen and of sulphur, suggesting it was semi-kilned, low carbon steel produced by the open-hearth process.

When seen through a microscope, steel has a grain-like structure. High levels of sulphur disrupt this pattern, creating a high degree of brittleness. Should the sulphur combine with magnesium in the steel, it will form magnesium sulphide, which in turn creates pathways for cracks to form. Titanic’s steel sulphur content is known to be high, even for the time.

This, combined with high levels of oxygen can turn steel from ductile (flexible) to brittle at relatively high temperatures. Titanic steel can transition from ductile to brittle anywhere between 25°C and 35°C. Modern steel goes through the same process at -60°.

Others have pointed to poor quality rivets used to hold steel plates together, rivets that would have exploded open when stressed by the impact weight of the collision, although Harland and Wolff have denied this hypothesis.

What couldn’t have helped

Notoriously, the number of lifeboats were reduced from the designed 48 to 20, perhaps because the designers were overconfident of the ship’s safety performance. More, the crew was not properly trained on matters of emergency evacuation. Thus, communication and coordination of the evacuation of passengers was piecemeal and incoherent.

Regulation hadn’t caught up with the technology of the time. The rules around lifeboat provision on British ships didn’t mandate the number of lifeboats according to passenger numbers, but to ship’s tonnage. These regulations had been written in the 1890s, but were not updated to take account of the rapid improvement, in maritime technology - and rapidly growing size (and thus, the growing number of people carried) of the steam powered passenger liners of the day.

How maritime travel was made safer

One result of the disaster is that international maritime laws were changed to include:

- The establishment of the International Convention for the Safety of Life at Sea, which is still in force today (with timely updates), to govern firefighting, vessel design, radio communication and navigation

- Mandatory lifeboat drills, and enough lifeboats for everyone aboard the vessel.

- 24 hour watch on radio communications, backed by a secondary power supply

- Retrofitting of double hulls to improve on double bottoms, and changes to the height of watertight bulkheads to make them truly watertight.

Titanic at the docks of Southampton, April, 1912. Source: Wikimedia Commons

While the Titanic disaster still captures our imagination through books, films, paintings, photographs and testament of the survivors, it is easy to forget the scale of the human tragedy. The ship was believed to be carrying 2,224 passengers on that voyage. There were lifeboats enough for only 1,178. Even so, approximately 1,514 people were lost with the ship, 710 people survived.

The youngest, and last lived survivor, Millvina Dean who was two months old when the ship when down, lived to the age of 97, dying in 2009. Her ashes were scattered at Southampton Docks.

---------------------------------------------------

How would such a disaster be avoided now?

How do we avoid this kind of over confidence in our technology?

By Stephen Phillips - IET Content Producer, with passions for history, engineering, tech and the sciences.

By Stephen Phillips - IET Content Producer, with passions for history, engineering, tech and the sciences.