Here is a summary of our recent panel session which brought together the Morrell Review of construction product testing, recent research by the IET into construction product manufacturers, and the Office for Product Safety and Standards (the UK regulator for construction products), to discuss digitisation of construction product data and how the Morrell Review views digitisation.

The IET Built Environment Panel has been working towards a better understanding of how construction product manufacturers can supply their product information to the construction supply chain in digital form. This work was prompted by the UK BIM Alliance (now nima) document ‘A Fresh Way Forward for Product Data: State of the Nation’ (2018) and led to the publication of ‘Digitisation for construction product manufacturers - a plain language guide’ in 2021.

Safe, reliable manufacturer information about construction products is essential to our industry and the safety of our buildings, and this has been recognised repeatedly in recent years. Six years on from Grenfell, we now have a Building Safety Regulator, a regulator for construction products, and will shortly receive the guidance on the Golden Thread of building safety information. And now we have the Morrell Review of construction product testing.

At Digital Construction Week in London on 18 May 2023 a panel session looked at the Morrell Review and a recent survey of manufacturers to identify what the challenges were to construction product information being available so that it is possible for these initiatives to deliver.

The panel was:

- Su Butcher, Director, Just Practising Limited – Chair

- Stuart Wheeldon, Operational Policy Manager at the Office for Product Safety and Standards (OPSS)

- Rick Hartwig,Built Environment Lead at the Institution of Engineering and Technology (IET)

- Paul Surin, Associate Partner Energy, Utilities, Engineering, Construction, AM/FM, Infrastructure, Real Estate, IBM

- Alex Small, Digital Platforms & Innovation lead at Tata Steel UK

Testing for a Safer Future: The Morrell Review

To start the session Su Butcher introduced an analysis of the Morrell Review.

In April 2023 the Independent Review of the Construction Products Testing Regime (entitled ‘Testing for a Safer Future’) was published. It seeks to answer the governments’ question,

“How should the UK system for testing the safety of construction products and the use of data from the system be strengthened, to inspire confidence that those products are safe and perform as labelled and marketed when incorporated into construction work?”.

The two person review panel were Paul Morrell (former Government Chief Construction Advisor) and Anneliese Day KC.

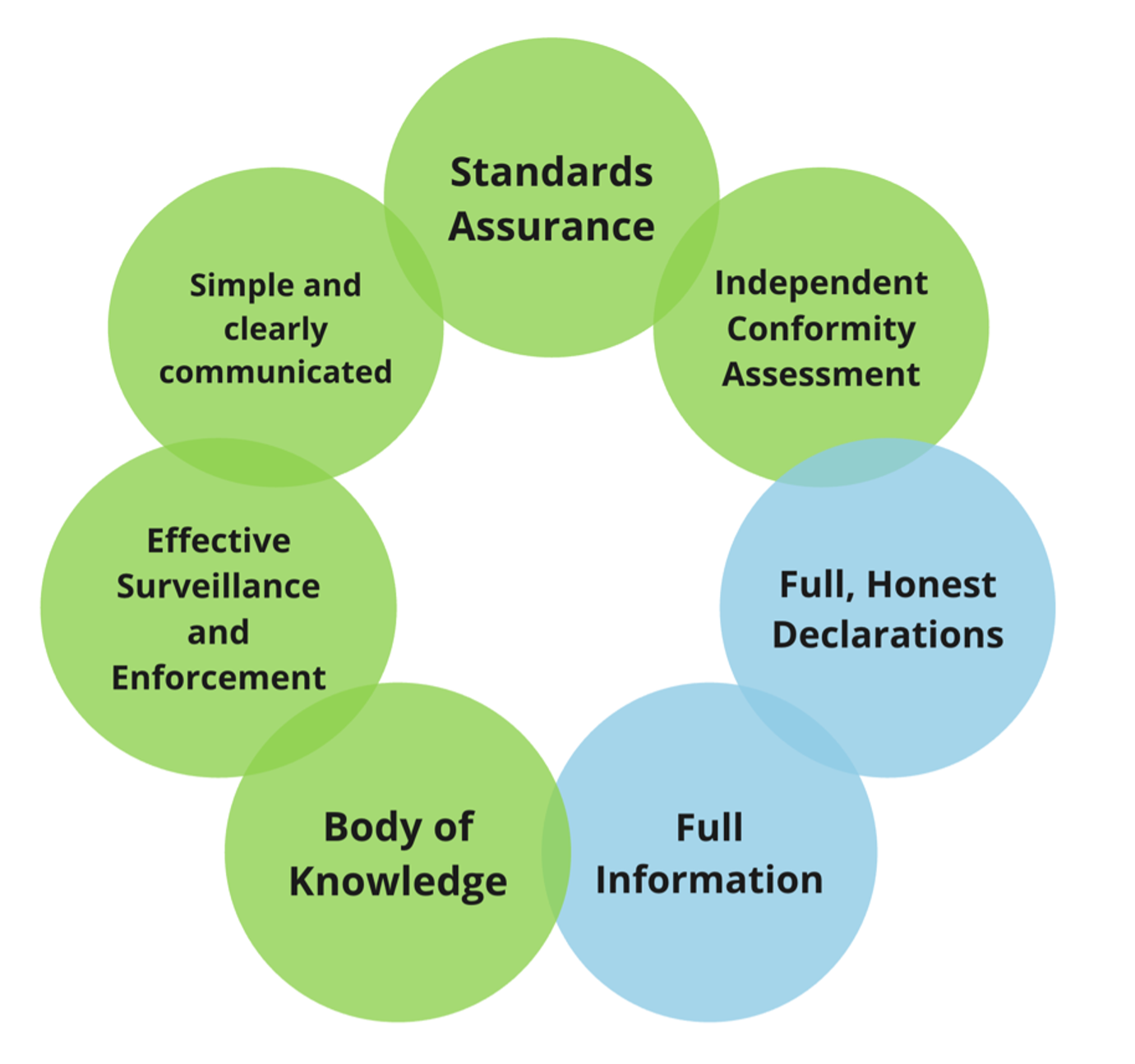

The purpose of the review is to show how “testing and the data derived from it can be restored as a public good.” Morrell sets out what a fully functional testing system should look like, which Su Butcher summarised as follows:

- Standards will deliver assurance of desired and defined outcomes, rather than just provide a means of comparing products.

- The conformity assessment process is conducted independently and is not compromised by commercial interests.

- Manufacturers make a full, honest declaration of the performance of their products, verified by reference to the assessment process, or by their own due diligence where independent conformity assessment is not prescribed.

- Declarations are backed by the information that designers, contractors and building managers need in order to specify, install and maintain products so that they match that performance safely.

- An organisational structure to to build and disseminate a body of knowledge about the prevention of fire in buildings and the behaviour of buildings in fire; and to raise the understanding of building safety and the priority given to it.

- An effective surveillance and enforcement regime, and

- The system itself and the way it is communicated should be simplified and clarified, so that compliance is not hindered by an actual or alleged lack of comprehension.

The Morrell Review: What a Fully Functioning Test Regime would look like

The emphasis here is firstly on plain language and better communications of all sorts, but also Morrell is committed to recognising the challenge, not bashing the industry. The document is huge, but it doesn’t pull any punches or avoid any of the key issues.

“Bringing about change… will not be achieved by exhortation alone, and still less by remonstration.”

Testing for a safer future, page 150

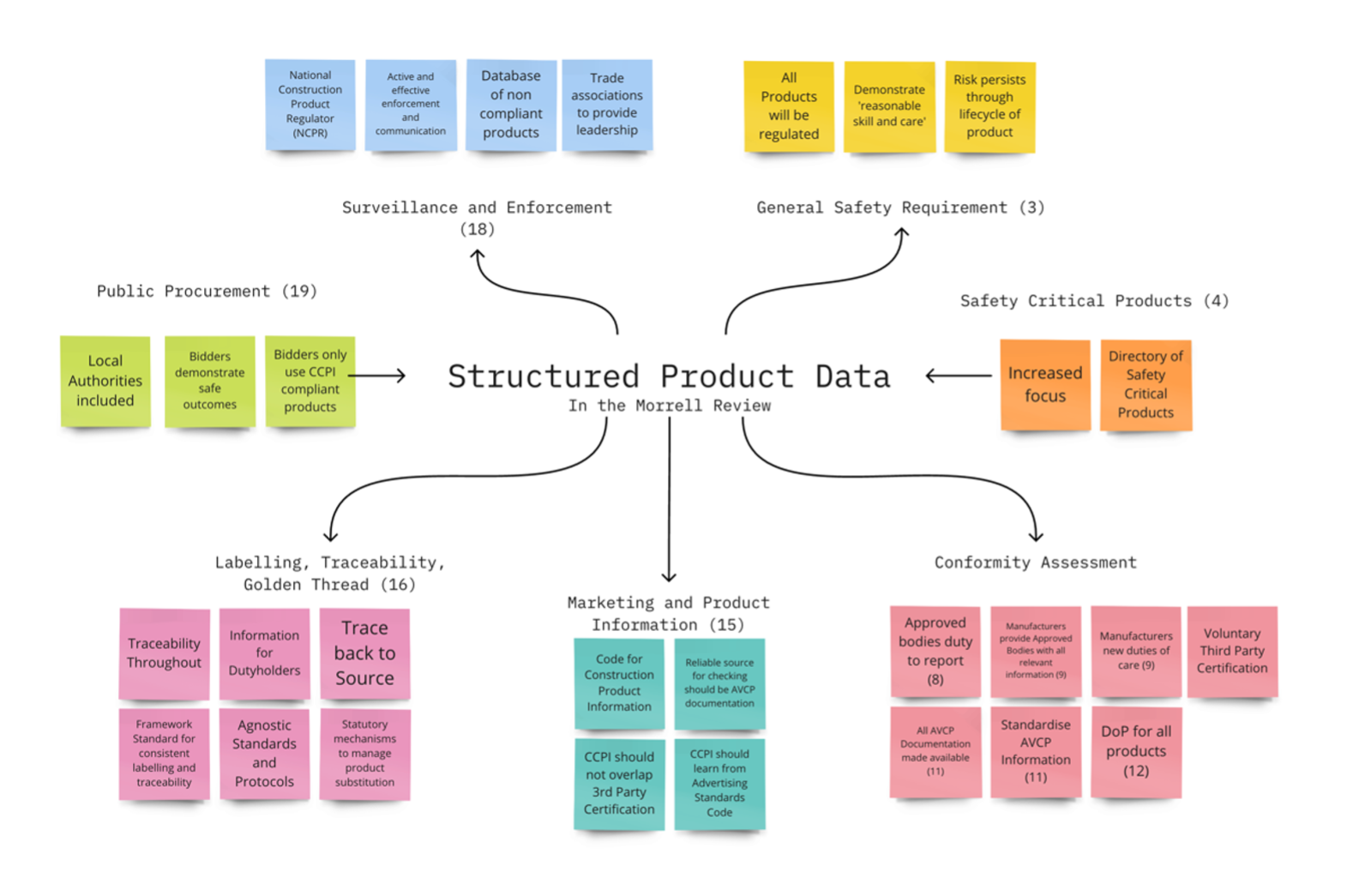

Recommendations from the Morrell Review related to structured product data

The review has 20 recommendations, including several which impact digital product information. Su grouped these into seven areas.

- General Safety Requirement (recommendation 3)

- Safety Critical Products (4)

- The Conformity Assessment Process (8,9,11,12)

- Marketing and Product Information (15)

- Labelling, Traceability and the Golden Thread (16)

- Public Procurement (19), and

- Surveillance and Enforcement (18).

During the panel session Su picked out three key areas:

The General Safety Requirement (Recommendation 3)

The Building Safety Act has already stipulated that all construction products should come under regulation of a sort, of a form which it describes as the ‘General Safety Requirement’. So this isn’t new. However Morrell and Day point out that this will place considerable additional responsibility on manufacturers. Government should frame the general safety requirement so that manufacturers can have a “reasonable skill and care” defense. Morrell and Day point out that risk continues through the lifecycle of a product, and the responsibilities of manufacturers, designers, constructors and occupiers of buildings should align.

The Conformity Assessment Process (Recommendations 8,9,11 and 12)

A wide range of recommendations cover the process of conformity assessment, which the review shows is not fit for purpose. Alongside recommending that government should consider requiring a Declaration of Performance (DoP) of some form for all construction products, the review argues that All AVCP documentation should be available.

Assessment and Verification of Constancy of Performance (AVCP) documentation is the record of all the activities which lead up to the production of a DoP – including classification reports and test reports. Morrell is saying that these documents should be made available in full, and if there is a genuine reason not to put them in the public domain, they will still need to be made available to the regulator. This is a substantial difference to the status quo but makes complete sense.

Ultimately Morrell is saying that the bottom line is that there is a reliable source for checking information, and that source should be the documentation that led to the declaration.

Labelling, Traceability and the Golden Thread (Recommendation 16)

At the core of the Morrell recommendations which require digitisation of construction product data is recommendation 16 which sets out the chain of custody of construction product information.

- Products should be traceable throughout their life, and the review sets out clear lines of communication.

- Government and industry should develop a framework standard for a consistent labelling and traceability system.

- There is a great deal about agnostic digital standards and protocols. Interoperability of information will prevent it ending up in ‘walled gardens’.

- Lastly, government should develop statutory mechanisms to manage product substitution and make clear where responsibility for all the implications of substitution falls.

It is worth reiterating that the Morrell Review is not government policy, rather it is a set of recommendations which should inform the forthcoming secondary legislation around construction products emerging from the Building Safety Act. It is hoped that draft regulations will be published later this year.

Where we are now: Results from survey of construction product manufacturers

Rick Hartwig, Built Environment Lead at the IET presented recent research into construction product manufacturers’ views on digitisation. 80 C-Suite level individuals whose companies supply construction products into the UK were interviewed by telephone in the first quarter of 2023.

What is digitisation?

Digitisation is turning your analogue and disconnected data into connected, digital form. It’s about connecting your sources of information together.

A digitised construction product manufacturer has a holistic data strategy that applies to all parts of its business, from operations to sales and marketing to logistics and to its upstream and downstream supply chains. With structured data, you will not have conflicting or duplicate information.

Examples of digitised work practices include:

- Product information on a company’s website is not updated manually but fed directly from a company product information management system (PIM)

- Sample requests are handled through connected CRM and product databases, rather than requests being emailed, printed out and actioned

- Certificates are downloaded from a verified website with change history, rather than a potentially out of date certificate emailed from a salesperson’s computer.

Here are some of the views which the research showed that manufacturers share on digitisation.

Manufacturers think digitisation is about admin and accounts

Most manufacturers believe digitisation is about admin and accounts or about emerging technologies such as robotics and AI. Digitisation of product information isn't on their radar and they aren’t thinking about supplying digitised, structure product information to the supply chain. Nevertheless, they know it makes sense - 80% think digitisation increases efficiency and profitability.

Manufacturers provide analogue Product Information

85% of manufacturers provide product information to customers via pdf or hard copy brochures. Only 31% provide product information via spreadsheets and very few via external sources such as third party websites or online portals.

This suggests that they are not providing structured data, and that the information available to their customers is unlikely to be up to date.

This is further confirmed by the result that 42% of manufacturers interviewed update the product information supplied to customers less than every six months.

Manufacturers therefore don't appear to value updating customers in real time or accurately. The vast majority are using a manual process, and therefore there is unlikely to be a reliable connection between manufacturers updating their products and updating the product information in the supply chain.

Only 8% of Manufacturers made or commissioned BIM Objects

As an interesting aside, only 8% of our sample had ever made or commissioned BIM objects.

This is astonishing given the enormous hype around the production of 3D BIM objects over the last decade, including surveys during which a large proportion of manufacturers stated that they were ‘BIM ready’.

Digitisation is a low priority for manufacturers

Whilst the vast majority of manufacturers say that digitisation increases efficiency and profitability, 92% do not see digitisation as a major concern. Less than half think it is a minor concern.

Manufacturers' concerns are primarily:

- cost increases

- materials supply

- protecting profit margins

- brand perception

- staff recruitment and retention

Other long-term factors such as carbon footprint and sustainability, or compliance with regulations and standards, also fall much lower in their priorities. Barriers to digitisation range from a perception that there is no need to digitise, to resource priorities being elsewhere.

In this climate, how will product manufacturers be able to provide trusted information to the supply chain?

The Product Regulator’s View

The panel was joined by Stuart Wheeldon of the Office for Product Safety and Standards (OPSS) who are the UK regulator for construction products.

The new Construction Product Regulations, together with new regulatory powers are expected in 2024. In the meantime, the regulator has been focusing on enforcing the current regulations, building capacity and capability, understanding the environment in which the regulations apply, and working with key stakeholders towards developing the right regulatory environment.

Stuart set out the huge challenge facing the new regulator. Firstly, the industry is not homogenous, rather a highly diverse set of subsectors, riven with fragmented ecosystems that encourage a diffusion of risk and the potential for abdication of responsibility among players in the system. The current, highly complex regulatory system is awaiting much needed reform. It is built around over 400 designated standards, outside of which regulations do not apply and was originally developed with a primary purpose of supporting the EU’s single market. There is very little incident data or primary research available to work with, which is why OPSS has developed its own research programme. This description chimes very much with that set out in the Morrell Review, which describes an abject lack of data, not only about the testing regime but even about manufacturers who sell into the UK.

The final challenge Stuart described is the low level of digitisation amongst manufacturers, which he explained reduces transparency and accuracy, hampers information exchange and can result in poor decision making. It also hampers effective 2 way traceability up and down the supply chain.

OPSS experience so far relating to product data identified several examples of the issues this causes:

- incorrect, insufficient or missing product information leading to misleading performance claims,

- poor information retention processes, creating difficulty locating product information for discontinued or historical products,

- delays in product information updates following changes to production, and

- difficulty tracing unsafe products from point of manufacture to incorporation in a building and from point of product failure to location and time of manufacture.

Stuart identified three recommendations of particular relevance to good practice through digitisation:

- R11 – AVCP documents: Making these documents available will support the consistent provision of pertinent information to enable effective decision making by designers, specifiers and buyers.

- R15 – Marketing the Code for Construction Product Information: By supporting good practice with clear, accurate, up-to-date, accessible and unambiguous product information.

- R16 – Labelling, Traceability and the Golden Thread: Linking to digital standardisation, supporting effective 2-way traceability, and striving for ease of access to relevant information in the golden thread (for all duty holders).

Digital Product Information is Coming

There is no doubt that structured, reliable, digitised construction product data will be essential to developing a reliable testing regime for construction products, and that it will form part of the new ecosystem for a safer built environment.

There is no doubt that structured, reliable, digitised construction product data will be essential to developing a reliable testing regime for construction products, and that it will form part of the new ecosystem for a safer built environment.

Manufacturers will need to provide structured information to their clients and the users of their products and will no longer be able to rely on basic websites and emailed pdf files.

If you’re a manufacturer and want to know where to start, download our free plain language guide to digitisation from the IET website here.