The global housing crisis is one of the most pressing challenges of our time, exacerbated by rising costs, population growth, and supply chain inefficiencies. Since the 2008 financial crisis, housing prices have consistently outpaced wage growth, making homeownership increasingly unattainable for middle and lower-income households. In countries like the UK, over 1.2 million people remain on social housing waiting lists, highlighting the urgent need for innovative, scalable, and cost-effective housing solutions.

Volumetric construction – where entire housing modules are built offsite in controlled environments and then assembled on-site – offers a transformative solution. By leveraging advanced manufacturing techniques, this method accelerates construction timelines, reduces costs, and enhances sustainability. Yet, despite its advantages, misconceptions around durability, financing, and adoption persist, slowing its widespread implementation.

This article explores the role of volumetric construction in addressing the housing crisis, examining global success stories, manufacturing innovations, and the necessary steps to unlock its full potential.

Housing as a social issue.

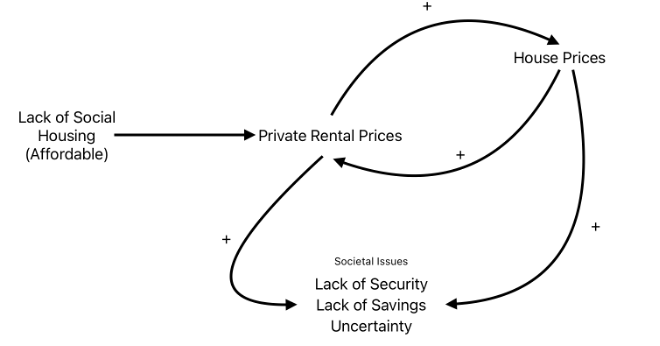

Figure 1: The Doom Loop for Housing

Since the 2008 financial crisis, housing costs have consistently outpaced wage growth, making homeownership increasingly unaffordable for middle and lower-income households. The lack of social housing has created a vicious circle for ordinary people.

The UK has a very large social housing waiting list, which has led to the growth of the private rental market, that in turn has raised private rental prices and house prices. The problems in society due to this can be seen in many people’s lived experience … in the UK surveys point to this housing as a key worry for ordinary people.

Innovative, scalable, and timely solutions are urgently needed to tackle this issue. All governments have the intention for affordable housing but how can this be delivered?

The Case for Volumetric Build

One of the United Nations Sustainable Business Development Goals is to have Resilient and Modular Infrastructure2. This highlights the need for volumetric construction, where completed 2D or 3D modules are manufactured offsite and assembled onsite. This approach aligns with the goal by addressing critical housing shortages efficiently and sustainably.

Industry stakeholders – including lenders, insurers, and homebuyers – often perceive modular homes as less robust than traditional brick-and-mortar structures. However, modern volumetric buildings adhere to rigorous structural standards, ensuring high durability, quality, and sustainability.

The benefits of volumetric build

- Efficiency and Speed

On-site assembly of volumetric homes can be completed in under two weeks, minimising construction waste, noise, and environmental disruption. From planning approval to tenant move-in, the entire project can be completed within just 3–4 months, ensuring rapid delivery of housing solutions. - Sustainability

Volumetric construction generates up to 90% less waste than traditional methods, significantly reducing carbon footprint and supporting the UN Sustainable Development Goals.

The Challenge

The key challenge in countries like the UK is the limited demand for volumetric housing, despite its clear benefits. If local authorities mandated a significant portion of new housing developments to use volumetric construction, economies of scale would drive down costs while ensuring higher build quality. Increased investment in this approach not only reduces costs but also enhances quality and fosters innovation through natural competition. As construction volumes increase, prices for units are likely to decrease.

Manufacturing Innovations

Advancements in manufacturing have enhanced volumetric construction across design, materials, and production efficiency.

- Robotics and Automation: The integration of robotics has enhanced precision and efficiency in module production. European modular companies have like NELCO and Renggli have incorporated robotics, making manufacturing more technology-driven.

- 3D Printing: The adoption of 3D concrete printing has enabled the creation of complex structures with reduced material waste. Notable projects, such as the Tecla3 house in Italy, demonstrate the potential of 3D-printed eco-friendly residential buildings.

- Building Information Modeling (BIM): The use of BIM software streamlines design and production, allowing for precise planning and reduced errors. For instance, the adoption of BIM360 has replaced traditional paper drawings, enhancing efficiency on the shop floor.

- Holographic Volumetric Additive Manufacturing: This emerging technology employs holographic phase modulation to improve light projection efficiency in 3D printing, potentially enhancing resolution and fabrication speed.

- Concrete Volumetric Modules: Asian markets have seen the rise of full volumetric concrete modules, providing durability and fire resistance for various building types.

While volumetric construction is still gaining traction in some regions, several countries have already embraced it as a mainstream solution to housing shortages. By integrating modular and offsite construction techniques into national housing policies, these nations have achieved greater efficiency, reduced environmental impact, and improved affordability.

Examples4 include:

- Sweden: 84% of new residential buildings use offsite methods; 80% of single-family homes are modular.

- The Netherlands: 47% of residential buildings are constructed offsite to address housing shortages with sustainable solutions.

- Belgium: 46% of homes utilise prefabrication.

- Poland: Rapid growth in modular construction, with 34% of homes built offsite.

The Way Forward

To harness the potential of volumetric building, countries should:

- Governments should mandate volumetric construction for a significant percentage of new social housing developments, ensuring scalability and efficiency.

- Construction industries need to further invest in volumetric manufacturing: using manufacturing innovation and scale production to reduce costs.

- Housing experts need to educate stakeholders and the public about the durability, quality, and sustainability of modular homes.

Volumetric construction presents a transformative solution to the housing crisis, leveraging advanced manufacturing to deliver high-quality, cost-effective, and sustainable homes at scale. Governments, investors, and industry leaders must act now to integrate this approach into mainstream housing policies, ensuring a more sustainable and affordable future for all.

What are your thoughts on the potential of volumetric construction to address the global housing crisis?

Which of the manufacturing innovations mentioned in the document (e.g., robotics, 3D printing, BIM) do you find most promising for the future of construction?

This article is written by:

Paul Johnson MIET

A Committee Member of the Manufacturing Technical Network. Paul was previously an Operations Director at a publicly traded volumetric construction company in Saudi Arabia, is a recognised expert in operational excellence. With extensive experience in manufacturing, process optimisation, and large-scale volumetric construction strategies.

Ketan Varia CEng MIET.

A committee member of the IET Manufacturing Technical Network. Ketan has worked with over 30 organisations in delivering operational change. His foundation is in Lean Manufacturing and has an interest in technology for social good.

References:

- "Wait List for Social Renting is 1.2M." *Office for National Statistics (ONS)*. https://www.gov.uk/government/statistics/social-housing-lettings-in-england-april-2021-to-march-2022/social-housing-lettings-in-england-tenants-april-2021-to-march-2022. Accessed 12 Dec. 2024.

- Business and Sustainable Development Commission. *Better Business, Better World.Jan. 2017, https://www.un.org/pga/71/wp-content/uploads/sites/40/2017/02/Better-Business-Better-World-Executive-Summary.pdf. Accessed 12 Dec. 2024.

- "TECLA – Technology and Clay." *Mario Cucinella Architects*, https://www.mcarchitects.it/en/projects/tecla-technology-and-clay.Accessed 11 Mar. 2025.

- *European Prefabricated Buildings Industry Study.* *Mordor Intelligence*, https://www.mordorintelligence.com/industry-reports/european-prefabricated-buildings-industry-study. Accessed 11 Mar. 2025.

- Salman, Ali. "The Critical Imperative of Government Support for Modular Construction." *LinkedIn*, 23 Aug. 2023, . Accessed 11 Mar. 2025.

- Morley, Jack Balderrama. “Production Line: How Sweden Is Pioneering Automated, Prefab Timber Construction.” Architizer, https://architizer.com/blog/inspiration/industry/swedish-modular-housing/.