To start thing off I have attached a couple of pictures of recent repairs I have made. Did it make sense to make these repairs? I think so.

Best regards

Roger

Denis McMahon:I have a Philips Philishave shaver, approaching 60 years old. The shaver still works and does not do a bad job of shaving. The problem is the mains lead - the conductors have fractured inside the insulation so power to the shaver is a bit intermittent and one needs to manipulate the lead carefully. The connector bit that plugs into the shaver is of a type one does not see any more. Philips has standardised on the type of connector that is widely used for small appliances like this. I am unable to get hold of this old type anywhere.

If faced with this problem I would probably cut away the plug until I could get to the end of the pins, solder on a new lead and the pot it in Araldite or similar. Some heatshrink to act as strain relief should complete the job.

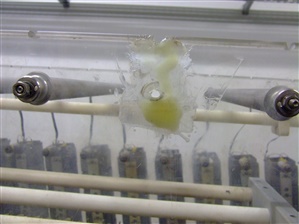

I have repaired a burnt rectifier stack plate on a 3 MeV electron accelerator with Araldite.

The burnt material was cut away with small round cutter in a Proxxon hand tool (similar to a Dremel)

And rebuilt in several steps with Rapid Araldite

The repair is still holding some years later.

Andy C:

. . .

Roger Bryant, regarding the tape machine I am currently converting a load of cassettes to MP3 using a couple of Radio Shack tape decks from 1983, still going strong, and the Sony hifi system I got back in 1978 sounds as good today as it did then, just need to sort out the crackle on the volume pots.

I have an early Sony Walkman. Originally it was intended as a portable compact cassette player used with headphones. In practice, many people used them to play cassettes through hi-fi amplifiers. The quality was reckoned to be pretty good. I use mine mainly to play cassettes into a computer, so I can produce mp3 files.

The mention of crackle on pots prompts me to my last post in this series. Around 1980 I had a colour television set whose picture would spontaneously degrade into "fringing" round the edges. Image edges would split into three representing primary colours. Then the picture would spontaneously restore itself. I opened the back, had a fiddle and tracked the fault to a "noisy" potentiometer on the convergence panel. Eventually, after some difficulty, I managed to find a shop that could sell me a suitable replacement potentiometer. (This was before the days of Maplin.)

I replaced the potentiometer. Then came the tricky job of setting up the convergence. I had no cross-hatch generator available. I used a live broadcast of Test Card F and, using the grid lines on that, managed quite well to get everything aligned.

COULD I DO SOMETHING LIKE THIS NOWADAYS?

Only with an old TV set. In the absence of analogue broadcasts it would need to be linked via a "set top box" to a video recorder containing a suitable image - not an insuperable problem. Modern flat-screen sets, using plasma, LCD, OLED, etc., technology are an entirely different ball game from cathode ray tubes, - and there is no such thing as convergence on them. They are however much more difficult to get into and service; it's all module replacement nowadays.

Andy Millar:

Yesterday I thought I'd better start my serious clear out of my workshop and various sheds (this is going to take months). One of the first things I threw out was an old washing machine motor that had been there for years. But I thought I'd keep the capacitor "just in case".

Tonight, the motor capacitor in our tumble dryer blew. And yes, it was 8uF

Sometimes life just works right(If that capacitor had blown two days ago I probably wouldn't have even remembered that I had one!)

Ah, capacitors! They play a crucial part. In our household we have a distribution amplifier which sends the aerial signal to TV sets, etc., around the house. One day, about a year or two before the so-called "digital-changeover", the TV pictures suddenly became unevenly illuminated. There would be a bright band at the top, merging into a dark band at the bottom. The bright band would move slowly downwards, until it was at the bottom, with a dark band then above it.

I decided this was a case of mains hum on vision. What could cause that? A failed smoothing capacitor, perhaps - that would cause hum on vision just as it would cause hum on sound in different circumstances.

I decided to open up the distribution amplifier and see if I could do anything in the absence of a circuit diagram and oscilloscope. Sure enough there was a large electrolytic capacitor in there. I decided there would be not much to lose if I were to replace it. I sourced from Maplin a capacitor, somewhat larger with a bigger PD rating. Popped it in to replace the old one. The distribution amplifier has worked properly ever since.

COULD I DO SOMETHING LIKE THIS NOWADAYS?

It is becoming more difficult, as circuit boards become more miniaturised and complex. Even in this case, the component joints were very small. I could not access the back of the board to do a decent soldering job. I managed to fix it but hardly in a professional manner.

Also, we are now in the age of digital broadcasting. With analogue reception, the quality of the picture gave a guide as to what was wrong, as in the case above. A grainy picture would suggest too weak a signal arriving at the set's aerial input, and would suggest where to look next for a fault, or if you were trying to receive a distant station, maybe you needed a pre-amplifier. With digital reception it is a perfect picture or nothing - much more difficult to diagnose.

Deborah-Claire McKenzie:

For those occasions when you just can't repair things yourself, here's an excellent spares website that I'd recommend as its kept quite a few of our household appliances and other items going for several years www.buyspares.co.uk

This is a good web site and I have used it myself on occasions. The trouble is that spares become less available over time and even sites like this cannot help. I have a Philips Philishave shaver, approaching 60 years old. The shaver still works and does not do a bad job of shaving. The problem is the mains lead - the conductors have fractured inside the insulation so power to the shaver is a bit intermittent and one needs to manipulate the lead carefully. The connector bit that plugs into the shaver is of a type one does not see any more. Philips has standardised on the type of connector that is widely used for small appliances like this. I am unable to get hold of this old type anywhere.

Oliver Stephen Hannaford-Day:

Thats a NiCad battery. PCB mounted batteries have a tendancy to do that if left alone for 15 years sadly.

The battery acid eats the tracks around the battery and worse, the copper out of the via's. The crystal case was destroyed too.

The crystal has now been replaced and any open circuit tracks have been remade but I think theres damage under some of the chips so will need to desolder the chips (and probably socket them) to check.

Fun times. :-)

I had a television set which one day lost all its channel tuning information. I was able to restore the information but it lost it all again the next time it was switched off. I had a look in the back and found indeed a similar NiCad cell looking in a sorry state, though there was 1·2 V across it with the set switched on. Fortunately the tracks were still in reasonable condition. I could not source an identical cell for replacement, so I just procured what I could - the wrong size so I hitched it to the board with flexible wires. It looked a mess but at least the set retained its tuning again. It lasted several more years, then one day the picture disappeared and it emitted lots of smoke. I decided it was time to send it to WEEE recycling.

COULD I DO SOMETHING LIKE THIS NOWADAYS?

It is getting more difficult. For instance I still have a video tape recorder, used on odd occasions, sometimes for copying video cassette to DVD. It retains the tuning channels OK but if it looses mains power the internal clock stops. Without a service manual I have been unable to identify a cell that would maintain the internal clock under loss of power. I once replaced a similar cell on a laptop computer a few years ago when I was still working. These cells are very small and difficult to distinguish from other components.

Lynne Collis:

Even cars are becoming more difficult to repair, apart from inserting new "black boxes". I could strip a Layland engine down to its con rods, but recently, our garage had to close its repair shop for two weeks while it waited for a new diagnostic computer.

If a headlight fails now, I can't just replace the bulb, it's a complete sealed unit that's required. I'm sure that's more profitable for Peugeot-Citroen, but it creates a lot of waste.

I used to tinker a bit with my early cars - change oil, change filters, change clutch cables even. One car had continuing problems with the carburettor. I lost count of how many times I had it to bits. One day in the early seventies I had the unpleasant experience, whilst driving through central London, of the engine cutting out and refusing to tick-over, though it would run as long as the accelerator was depressed. I managed to find a place to park somewhere I shouldn't and carried out roadside repairs. I dismantled the carburettor and blew the idler jet clear. Reassembled and all OK again.

COULD I DO SOMETHING LIKE THIS NOWADAYS?

No way! As Lynne says, it's all "black boxes" nowadays. Fuel management systems and such like. They are very clever, I agree. Does anyone remember choke controls, cold engine problems, "flat spots"? Consigned to the dim past. It is even possible to climb a 1 in 12 gradient just on the tickover (yes, I tried it once). Failures are rare but if they do go wrong it can be very wrong. I would call the RAC and leave it to the experts with the tools and the know-how.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site