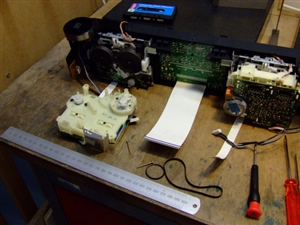

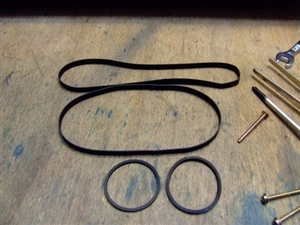

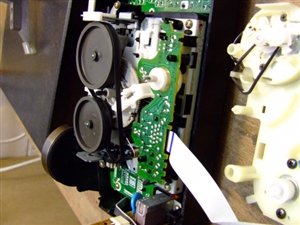

To start thing off I have attached a couple of pictures of recent repairs I have made. Did it make sense to make these repairs? I think so.

Best regards

Roger

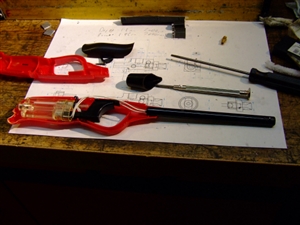

An electrical based repair this time.

We had a couple of gas lighters that would no longer light. A spark was visible when you pulled the trigger and the gas could be lit with another flame but they would not self ignite. Dismantling them was the hardest task, trying to work out how to spring off the clipped on parts without breaking them. Once inside the problem appeared to be a buildup of soot and candle wax around the spring nozzle. I don't understand why the nozzle needs to be a piece of spring but that's what it is. A good cleanup, reassemble and ignition ?

Was this economically justified? Probably not, but they didn't end up in the waste stream.

Best regards

Roger

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site