We can all learn from other peoples mistakes: poor wiring husbandry, but worse still - failure to comply with product drawings. One could deduce that this was Human Factors Violation! Sadly the report did not investigate the maintenance error:

'it is possible to consider that there has not been full adherence, on the part of those responsible for assembly, to the requirements established by the manufacturer'.

A resume of the report is below.

Embraer ERJ-190 EWIS Production Quality a Factor in Fire (Azul PR-AUO)

On 21 February 2017 Azul Linhas Aéreas Embraer ERJ-195AR (ERJ-190-200 IGW) PR-AUO was at approximately 14,000ft on descent Vitória, Espirito Santo, Brazil. A short circuit occurred with overheating and sparks inside the cabin near seat 03A. A cabin crew member discharged two fire extinguishers after using a fire axe to get better access. The pilot declared an emergency and a safe landing was accomplished without any injuries.

The Brazilian accident investigation agency CENIPA explained in their safety investigation report (dated 2 October 2020: only available in Portuguese) that the aircraft suffered damage to the cabin trim sidewall.

EWIS Fire Damage to Azul Linhas Aéreas Embraer ERJ-195AR (ERJ-190-200 IGW) PR-AUO (Credit: CENIPA)

Between the sidewall and the aircraft’s external skin, as well as structure there is a thermal / acoustic barrier, wiring and an electromagnetic protection blanket. Upon removal of the sidewall the source of the fire was identified as being related to Electrical Wiring Interconnection Systems (EWIS). Several wires had melted, characteristic of a short circuit.

EWIS Fire Damage Azul Linhas Aéreas Embraer ERJ-195AR (ERJ-190-200 IGW) PR-AUO (Credit: CENIPA)

The affected wiring was PN 191-32836-401. The damage was located near the P1143 electrical connector. The affected conductors were part of two different circuits:

One of these circuits connected the AC BUS to the Left Integrated Control Center (LICC) and the direct current (DC) Windshield Heating Control Unit 2.

The other circuit connected the AC GND SVC, located at LICC, to the Secondary Power Distribution Assembly (SPDA1), for the control and monitoring of energy for electrical system components.

The associated circuit breakers (CBs) had both tripped and it is that, rather than the fire-fighting, which CENIPA believe resulted in the fire ceasing. The CBs were tested and found to meet their specification.

When wiring adjacent to seat 3D, on the opposite side of the cabin, was examined there was evidence of chafing between the wiring and the electromagnetic protection blanket.

EWIS Chafing on Opposite Side of Cabin – Azul Linhas Aéreas Embraer ERJ-195AR (ERJ-190-200 IGW) PR-AUO (Credit: CENIPA)

Investigators then examined PR-AUM and PR-AUP, two aircraft with serial numbers close to that of the PR-AUO. Further chafing was observed on both those aircraft.

EWIS Damage – Azul Linhas Aéreas Embraer ERJ-195AR (ERJ-190-200 IGW) PR-AUM (Credit: CENIPA)

EWIS Chafing – Azul Linhas Aéreas Embraer ERJ-195AR (ERJ-190-200 IGW) PR-AUP (Credit: CENIPA)

While the Maintenance Review Board (MRB) for the type had identified the need for a periodic inspection of the general condition of the wiring, this was scheduled for every 36,000 flying hours. PR-AUO aircraft had flown only 4,047 hours. PR-AUP and PR-AUM also had less than 5,000 hours. A check of maintenance records for these aircraft confirmed the wiring harnesses had not been disturbed in-service.

The investigators confirmed that:

Contact between the sidewall and the wiring allowed relative movement and consequent friction between the parts. The friction resulted in loss of material from the surfaces in contact. Due to its physical characteristics, the process of material loss in the wiring was more accentuated and consumed the insulating material of the cable, allowing the exposure of the conductive wire. This scenario favoured the occurrence of the short circuit.

The short circuit between the conductors led to the collapse of the systems fed by these wires. However, the affected systems had specific redundancies and protections, such as CBs…

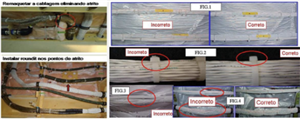

CENIPA verified that there were appropriate production instructions for wiring installation but that production quality deviations had occurred on the aircraft examined.

EWIS Build Instruction Example for Embraer ERJ-190 Series (Credit: via CENIPA)

The investigators expressed concern on the use of the fire axe:

The place where the hatchet was used in the occurrence was an area where several power cables passed from the aircraft systems. An eventual cut of one of these harnesses could result in a larger occurrence.

ANAC regulations, as well as the company’s and manufacturer’s flight attendant training manuals, did not specify in detail how to use this equipment, notably with regard to the necessary care to avoid aggravating the aircraft’s condition.

CENIPA Conclusions

The manufacturer established wiring installation requirements in order to avoid friction between its elements. However, it was observed that the short circuit occurred due to the contact between conductive wires, which lost insulation material due to friction between the wiring and the reverse side of the sidewall.

Worn wiring was found in other sections on the same aircraft, as well as in two other aircraft produced in the same context. Thus, it is possible to consider that there has not been full adherence, on the part of those responsible for assembly, to the requirements established by the manufacturer.

CENIPA raised 6 recommendations on wiring installation and cabin safety.