Long ago I started a thread on the maker movement and mending things:

https://engx.theiet.org/f/discussions/20498/maker-movement-mending-things

To avoid the original being broken up in ‘tree’ format I will start a new one. Maybe it will survive in a readable format.

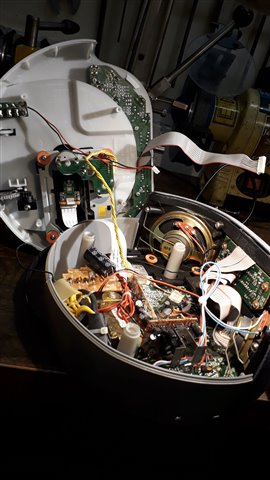

The minute set button on my 20 year old Radio/CD/Alarm Clock stopped working which made it somewhat useless. I don’t want a mobile phone by my bed so I decided to try and mend it. There were some buttons I have never used, program for example, so I hoped that the switches were identical and I could swap them.

The top was held on with 3 screws. The lead for the CD Laser safety switch was very short so it had to be disconnected to get the top off. A sensible safety precaution. Four more screws and a multipin connector released the switch PCB. A quick check with a multimeter confirmed that the minute set switch was faulty and the program switch was good.

A few minutes work with a soldering iron and solder sucker and the switches were exchanged. They were also used a PCB track bridges so I couldn’t just leave one out.

Plug the cables back in, screw it back together and test. Ready for the next 20 years