Good evening.

We have found a series of issues whilst performing solar maintenance and testing on a metal framed and cladded building (including the roof).

The System:

installed in 2015

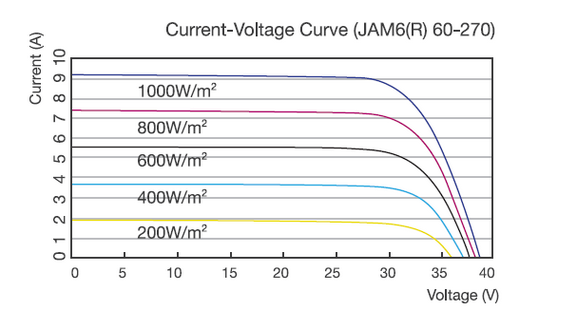

442 Panels installed over 22 Strings. Panels installed JA Solar - JAM6-R-60/275 JA Modules

The system is 3 phase and comprises of four 20kW three phase inverters (AC coupled)

No Batteries on site. No earth spikes found. The PV array frames and mounting are directly attached to the metal structure

The DC string voltage ranges from 700-800V DC on the healthy strings. No string surge protection. No string over current protection. Just panels directly connected to inverters via 4mm solar PVC cables

System Condition:

Many panels are damaged/broken. Some with holes tennis ball size in. Heavy seagull damage. Lots of fauna growing between panels.

Site weather conditions:

Foggy and Raining

The Fault:

Of the 22 Strings 17 have faults to earth. Insulation Resistance tests (1000V DC test voltage) were attempted from both Positive and Negative MC4 connectors (taken out of the inverters) to earth (the structure). The IR test was not possible as we were getting 600-800V from both positive to earth and negative to earth. We do find voltage during these test normally, but it generally dissipates down to a level were we can test within 2-10 seconds. This is commonly known as a RISO issue, i'm aware. On the healthy strings we were getting 0.1 - 3 Mohms.

I'm aware we can test which panel is likely causing an issue by taking the volts present between P-E and dividing this by the individual panel Voc.

My question is:

Even with the inverter DC isolators in the open position (Off), on all 22 strings, is there a risk to life or a chance of fire with the system in its current condition.

Does the building structure pose a risk of electrocution? (nearest building 35m). Trucks and vehicles are operating within the building 12 hours a day.

Fault example: If we had a P-E fault on panel 1 of 20, and a negative to earth fault on panel 20 of 20 you could get a short circuit.

Action taken:

We have issued a danger notice whilst we investigate this further. This was suggested by our accrediting body as well. They are currently looking at this with us to help find a solution.

Any thoughts or solutions welcome.