Hello, I am hoping someone will be able to help with an issue that I am having with a Permanent Magnet Generator.

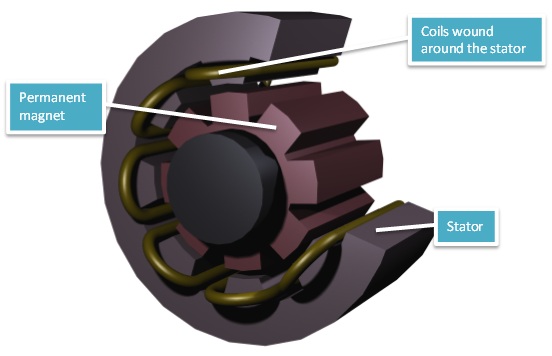

As a bit of background, the generator is connected to a turbine and thus converts mechanical torque on the shaft into electrical power. With it being synchronous the Voltage is proportional to the speed. A Variable Speed Drive is used to vary the speed to maximise the output from the turbine. The generator has 12 poles.

During initial installation, the generator was found to have been supplied to the incorrect specification. It was supplied with the wrong number of poles and wound for 400V/60Hz; it therefore produced excessive voltage for a given speed. The generator was removed from service and rewound to an unconventional 400V/95Hz. The rotor and the stator designs were unchanged. The number of turns has been reduced by 37%. I don’t have any data on the wire gauge.

Since the being rewound to the new design, the generator is producing less voltage than expected. The new windings should deliver 42V/ 100rpm, but it is fact delivering only 35V/100rpm. This is resulting in a shortfall of power. The generator has been rewound again, to the new design, with the same result. The new windings have resulted in a lower power output than was achieved with the initial windings.

Only the winding design has been changed. There is no reason to suspect a reduction in torque from the turbine or damage from bearings etc. The operation and control from the VSD have been extensively looked at and deemed not to be the issue.

My suspicion is a reduction in the magnetic flux, either from excessive leakage or possible damage to the magnets, but I am far from an expert. While reverting to the old design seems an obvious solution, I am keen to understand the exact nature of the problem.

I am reaching out to see if anyone can share some suggestions as to any possible causes of this issue.