Standard cable gland, Stuffing cable gland and Insulated cable gland - their definitions and application.

Standard cable gland, Stuffing cable gland and Insulated cable gland - their definitions and application.

Hi Dhanraj

Thank you for your question! Could you please elaborate a bit more on your query to help the community to understand what help you're looking for?

For example, what is the background or scenario related to your question? Are you working on a specific project or facing a particular challenge? Are there any specific aspects or components you are particularly interested in? Are you looking for information on installation, maintenance, or specific types of cable glands? What is the main goal or outcome you are hoping to achieve with this information? Understanding what you're trying to do will help our community members to tailor their response to better meet your needs.

Lisa

Not sure about definitions, but in common usage:

Cable gland - could be any kind of cable gland, insulating or metallic, for armoured or plain cables.

Insulated cable gland - generally a gland made from insulating material (plastic). There are also some specialized glands of mostly metallic construction but with an insulating layer that are intended to "gap" (insulate) a cable armour from a metallic enclosure (e.g. when different earthing systems meet) - but they're few and far between. Glands that connect to the armour or braid of a cable tend to be metallic (although there are some composite ones on the market now).

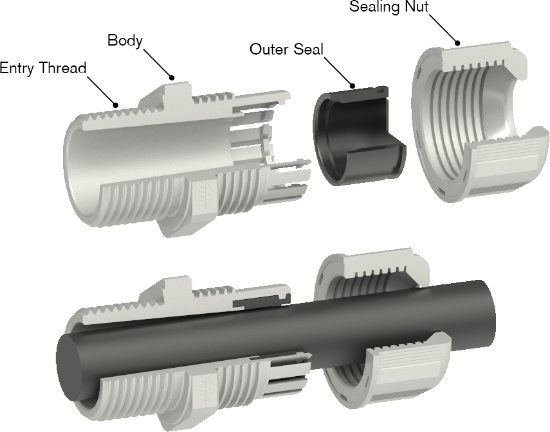

Stuffing gland - a gland that grips and seals by compressing some "stuffing" - these days that's likely to be a soft rubber or plastic doughnut shaped ring. Normally used with simple sheathed cables, but occasionally used with armoured cables where a connection to the armour is positively not wanted. The body of the gland may be metallic or insulating, but plastic is most common these days.

- Andy.

I broadly agree with the above. Here are some examples of the sort of thing.

I don't think you'll find formal regs grade definitions, but in the electrical world at least. 'stuffing glands' usually provide some degree of waterproofing to some IP rating - the compression of the sealing material 'stuffed' against the cable jacket has to be the right size for the cable chosen however. Also called a compression gland, and easily compromised by a poor entry seal between the body and the box it is entering even when the seal to the cable is perfect.

Insulating stuffing gland.

Note also that stranded cables leak between the ends as there is a gap between the wire strands..

Insulating glands do not provide electrical continuity between cable armour and a metal box. Any other gland, may or may not but is not specifically designed to do so.

Some are very much designed to afford a grounding function.![]()

This is both a stuffing gland, and metallic and designed to earth an armoured cable.

compare with this cheaper indoor only metallic gland, still does the earthing but not watertight nor a stuffing design.

Mike.

Thanks for your reply! Andy

Thanks for your reply! Mike

Noted, Lisa. From my next question/discussion I will follow the above.

You MAY find this link helpful

I found this article after a web search on the assumption you may have been looking at how the terminology came about and why it might be confusing (been there )

amphenol-industrial.com/.../ "The Fascinating History of Cable Glands: From Cloth to Cutting-Edge - Amphenol Industrial Operations".

Hopefully useful background

perhaps be aware that 'knob & tube' wiring depicted in that article is a peculiarly North American thing, at the same time over here we were using India rubber double cloth covered indoors and the wire was insulated along the full length - perhaps the use of higher voltages drove that decision. The use of singles stapled to wooden joists was common, though in better installations it appeared within split wall " slip" conduit.

Outdoors we had indoor cables in welded galvanized conduit or paper insulated lead clad , where the paper was oiled. There is a fair amount of that still in use underground today, and if it was not so hard (expensive) to make and join we'd probably still be using it. Somewhere between the late 1930s and the present day, mineral insulated copper clad came and went as well - and that uses a lot of glands.

Mike.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site