davezawadi:

Andy

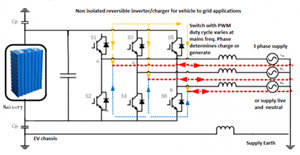

In the separated system there is no danger from a charging live to chassis fault, unless there is also some way of accessing the neutral as well, which is connected to the PE connection and with my suggested arrangement will immediately trip the RCD. Remember nothing on the secondary side of the isolating transformer is connected to real earth, nor any Protective Earth connection. Moving to the block diagram, there is complete isolation between the charging supply and the charger output which is illustrated by the dotted line. This is the exact point at which double insulation may be applied, and would be conventionally done so in a normal class 2 power supply unit. If signalling is required along the earth wire (presumably the earth neutral loop), it also needs class 2 isolation but this is not beyond the wit of man to design. A worldwide standard needs to match all possible systems in use, it would be reasonable to have a list of who suggested what (daft) idea, and who voted it through!

I am almost disgusted by Graham's comment that "its in product standard" or words to that effect, because a faulty product standard is no excuse to continue to use it, for example cladding for buildings!! The job of the standards committee is to produce proper and safe standards, and this should be completely isolated from any manufacturer or other political pressure. This also does not appear to be the case with BS7671. I have sat on standardisation committees in the past and a major issue has always been from manufacturers who are not prepared to change their own ideas, although they send often unskilled persons as representatives. A manufacturer trying to save tiny amounts of money in the design of the car is foolish beyond words, the reliability and safety of the car must be considered first, as both are the way reputations can be lost very quickly.

davezawadi:

Graham

It is easy to say that, but the car case is subject to a new(ish) standard, and some expect it to become common. I could treat it exactly like a caravan, but in reality it is probably more dangerous and TT is only a partial answer. The main difficulty is that cars are charged near PME earthed locations (garages, garden taps etc.), and at the same time the PME system is broken due to poor maintenance. Our answer is to make a fairly unsatisfactory set of regulations (I think most qualified people agree), and worry about the problems on a forum. Yes, the UK should permit only class 2 cars for new sales! The owners of the present vehicles would have the same problem that diesel drivers have, they changed the rules. They were changed to make the country safer, why not? CUs were changed to metal for "safety", why not cars?

Remember nothing on the secondary side of the isolating transformer is connected to real earth, nor any Protective Earth connection.

Moving to the block diagram, there is complete isolation between the charging supply and the charger output which is illustrated by the dotted line.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site