Hello,

anyone into electronics to help me (I have some suspects).

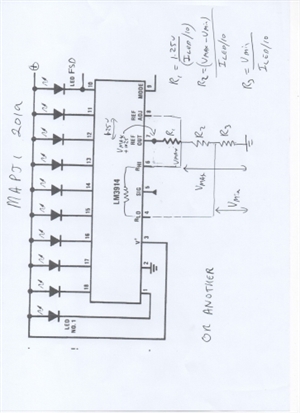

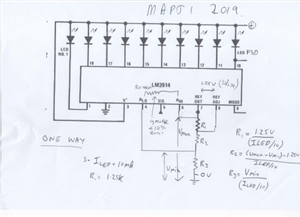

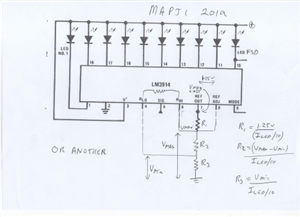

I am having trouble with LM 3914/5/6

I get the current program of LEDs by making path to ground 0V from Pin 7.

Pins 7 & 8 give use approx 1.25 volt ref

It`s the pin 6 & pin 4 Rhi and Rlo bits in order to get values of other than the supply lines.

i.e if we put in two resistors R1 & R2 from pin 7 to 0V and calculate the voltage at the junction then we could use this as a hi or low I think but what about the other (to get a hi and a lo) .

Then methinks factor in the internal comparitor divider chain into these figures to see if a significant variation occours .

I initially want to prog my LEDs to say 10 or maybe 15mA current and the hi and low volt comparisons say 1.8v to 4.0v.

Thanks