There seems to be some slight differences with regards to acceptable Zs values when comparing the two documents BS7671 17th Edition A3 and Guidance Note 3 Inspection and Testing 17th Edition A3.

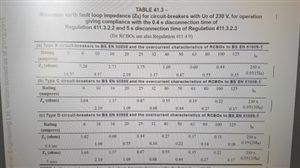

For example table 41.3 from BS7671 17th Edition A3 states:

0.4sec trip D6A = 1.82 Ω

Adjusted to 80% as per appendix 14 = 1.456 Ω

However page 121 from Guidance Note 3 Inspection and Testing 17th Edition A3 states:

0.4sec trip D6A = 1.46 Ω

These two documents are produced by IET. Guidance Note 3 Inspection and Testing 17th Edition A3 is rounding up Zs values above the maximum allowable values detailed in BS7671 17th Edition A3, why is that ?