Wolfie100:

I have two outbuildings going up and I am getting myself tied up in knots trying to decide exactly how I going to do it. Bit of background, this is a DIY installation under BC that will be inspected and tested by an electrician appointed by BC. I need to pass on first test as subsequent tests are expensive. I have a number of questions where the experience of the forum members will be helpful.

Q1) cables to the electrode - In selecting a most likely spot where I will get an earth rod into the ground (fairly hard chalk, overlaid with clay type soil) I am getting confused by some of the terms in the OSG. Table 4.2 ( from the 17th, awaiting for 18th) states that I can gor for a little as 2.5mm2. However, when buried, it goes to 4mm2 for mechanical damage protected, 16MM for corrosion protected and 25mm unprotected. What constitutes mechanical and corrosion protection? Does the PVC insulation on single core cable provide corrosion protection? if not, can someone point me at a cable type that has a suitable sheath layer that does? With regards to mechanical protection, I presume I am again looking at cable tiles/concrete sections or steel pipe protection? or given the danger to the person digging is less significant, would a steel flexible conduit suffice? I do appreciate that a cable break would leave a dangerous condition in the outbuilding.

Q2 - Earth rods 1 - I fear I am going to struggle to get the earth resistance down to a good figure, aiming for sub 50 ohms. I am not clear what gives me a better chance, one deep rod or two shallower rods (around 3m apart). Depth may be a real problem into the chalk (peppered with flints!). My soil conditions vary, around one installation, the soil is is fairly rich for about 30cm, then clay mixed with stones for another 30cm down to chalk. The other area is not as good, it doesn't have the soil (well 5cm or so).

Q3) What is the correct way to connect multiple rods, single cable CU - Rod1 - Rod2 etc,?

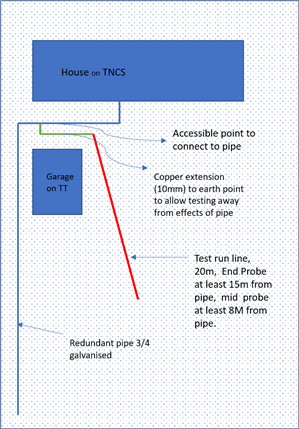

Q4 - Earth rod alternatives - I have two redundant galvanised steel pipes, 1/2 inch that are about 45m long, both are buried at a good depth and completely disconnected at each end. They run in parallel for most of their length and are about 1.5 m apart. Could I use these to supplement my rods? could I just use them without rods? if so, do you think my Inspector/tester will have any issues as long as my Ra is satisfactory.

Thanks in advance for any advice offered.

Mike

Your lengths of redundant disconnected galvanised steel water pipe will provide good earthing and can serve as earth electrodes, and will no doubt be better than any 4 foot long earth rod. 542.2.2.(vii). You can join them together if you wish.

I presume that you are providing a TT earthing system at the outbuildings with 30mA R.C.D.s for all final circuits, as any earth rod or other type of electrode will not in itself normally comply if you are just using M.C.B.s or fuses.

Table 54.1 refers to BURIED earthing conductors. So if you provide earthing pits and the earthing conductor is not buried it will not apply. We normally use a 16.0mm2 green and yellow single cable for earthing conductors connected to earth electrodes in domestic properties.

It sounds as though you need to employ an experienced and qualified electrician for this job.

Z.

Wolfie100:

Thank you. I am going to give the galvanised pipe a go. I will have use of an earth resistance tester this weekend so will check it out. Apologies for more questions, what would you use to connect to the pipe? I assume a standard bonding strap in unsuitable. Most connectors I have seen so far are for 5/8 or 3/4 rods. I could drill the pipe where exposed and get a nut and bolt through with a plate to form a clamp. Do I need to be concerned with the reactivity between copper/zinc?

I would use a B.S. 951 bonding clamp for the connection to the earth electrode old water pipes, in an earth pit with cover and warning label. The standard size is up to 35mm dia. according to the box details on mine. Larger straps are available. The outdoor "wet" type are necessary to avoid corrosion. (Blue label or better). I would not drill holes into the old water pipes as that may attract corrosion.

Z.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site