Hi.

Have a question on voltages and equipment regarding a PAT test option.

On some equipment, like motors, if the voltage drops below the minimum, damage can occur. In the case of motors, from overheating.

Not sure what the effect would be on electronics. I believe the inductive reactance may reduce like it would if the frequency went down. Not sure if it's the same case with voltage.

I was looking up PAT testers the other day. I did the C&G PAT course years ago and the last time I used PAT tester is about 15 years ago.

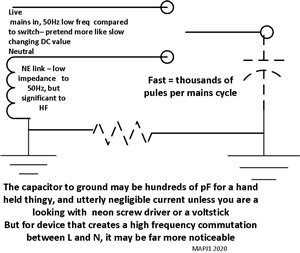

There is now an option to do a "Substitute leakage current test".

Depending on the tester it is between 60 & 100 volts.

I would have thought the only way to get leakage is for the equipment to be running and that would take full voltage.

I can't see how using a voltage so low will get a leakage result. I'm also wondering if there is any adverse effect on the equipment. I scanned through the Fluke manual and it didn't have any restrictions on the type of equipment.

I know they are unlikely to produce the tester with this test if it damaged equipment.

I'm theorising that even if equipment can get damaged if the voltage drops below the minimum, the test voltages that are much lower are not enough to run equipment so no damage can occur.

Still can't see how you can get a leakage result though.

Any thoughts?