it pulled back slightly which was a bit concerning

aligarjon:

I only use the levers if i am connecting a flex as i have never been able to push one into the standard Wago without it just bending over. If you need to get a smaller cable out of the standard Wago without destroying it, so maybe to test. If you push another core of the same size up along side it will pull out with a gentle wiggle if you are careful (I have only tried it with 1.0mm)

Yes, I don't think that the ordinary ones are intended for flex, but there are the straight through ones for lighting with a sort of push button for release.

I have just tried the second wire trick. It worked for 1.5 mm² and 1.0 mm², but the second wire tends to catch! However, if you use a scrap for the second wire, it can suffer a bit of abuse when you pull it out. 2 x 2.5 mm² doesn't fit. Another good tip! ?

For the non-lever types, I suspect it would be just a matter of the retaining spring/blade 'biting' into the conductor - so if anything the pull should make it more secure rather than weakening anything

Andy, do the lever type and non lever type grip in a different way? I thought that there was a blade, spring mechanism in both

aligarjon:

I only use the levers if i am connecting a flex as i have never been able to push one into the standard Wago without it just bending over. If you need to get a smaller cable out of the standard Wago without destroying it, so maybe to test. If you push another core of the same size up along side it will pull out with a gentle wiggle if you are careful (I have only tried it with 1.0mm)

Gary

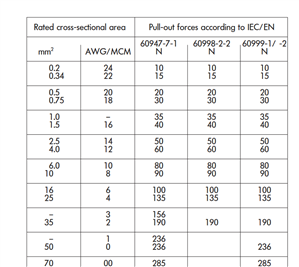

Some Wago's, like the 773's, are only suitable for Class 1 (solid) and Class 2 (stranded) conductors (both of these would come under the denomination "sol" used by some manufacturers). To the best of my knowledge, the Wago's are all marked in some way with the wire types they will terminate - moulded in the plastic so you might need specs in poor light though.

The 221's and 222's do Class 1, 2, and 5 (Flexible) but not Class 6 (Extra-flexible).

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site