Nathaniel:

Actual MCBs that aren't antique tend to operate on high currents in well less than a half-cycle, as has been suggested here already: they are "current limiting", so they can force the current to a zero before its natural zero-crossing. But the wiring regulations give the curves going down to 100 ms (not 10 ms). Presumably that's because it's all that can be guaranteed for an MCB according to the expected product standard. In my ~20 year old copy of IEC60898 I see no requirement to be quicker than 100 ms for any fault current; no requirement on let-through either, except that a specification of it should be available to the product's user. So if you go only by what the standard requires, the let-through could be absurdly high. It's necessary to use the manufacturer's let-through specification to avoid depending on the 100 ms assumption, but I don't see what the regs can improve if the product standards don't specify more.

As an historical note, if you go back to the earlier editions of the wiring regs (e.g. early 16th Ed - probably just before it became BS 7671) - the full curves are there for MCBs.

I haven't checked, but I suspect that change coincided with the advise to use energy let-though data rather than "time" when calculating for the adiabatic once you reached the magnetic region of operation. As Mike mentioned, "t" gets a bit wobbly with short disconnection times as a lot then starts to depend on quite where in the a.c. current cycle the fault appears - as if it all starts in the wrong part of the cycle there may be quite a delay of a portion of a cycle until the current gets high enough for the magnetics to kick in - even though the effect on the overall energy let-through is small.

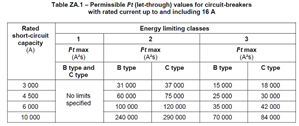

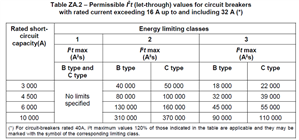

It sounds like BS EN 60898 has changed a bit over the years. They copy I've seen had an Annexe ZA with various energy let-though figure. Oddly (and annoyingly) they're keyed on rated breaking capacity of the MCB rather than the actual fault current. Most are energy class 3 these days I think.

(hopefully it's within the copyright rules to use a couple of small extracts for academic discussion..)

- Andy.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site