ProMbrooke:Right, but what has me perplexed are the lack of tables in part 7. Exception being medical locations however this should apply to all kitchens, bathrooms, laundry areas, garages, unfinished basements, exterior sockets, pool circuits and the like- anywhere skin conductivity is lowered typically through moisture or large earthed surfaces.

Bonding and RCDs should not be the primary means to achieve protection in these areas. Rather a pyramid approach should be taken imo. Remote earth is impossible to avoid in all scenerios. RCDs have much higher failure rates compared to MCBs. Yet ADS remains the most simple, assured and reliable way of protecting life and property.

Disconnection time may not be the answer, so that's why no tables.Where RCDs are specified, you're practically there already (0.04 s disconnection time OK for U0 230 V and your "Wet" table).

In terms of other locations, there is a need to take into account other issues, such as the clothing and footwear people are likely to be wearing etc - which change the touch voltages and disconnection times also. See IEC TR 60479-5:2007. IEC60479 : 2007 Effects of current on human beings and livestock –. Part 5:Touch voltage threshold values for physiological effects

gkenyon:ProMbrooke:Would these be for mainland Europe where bathrooms may not have supplemental bonding?

I personally would not rely on bonding alone in wet locations, in particular exterior sockets where earth mat is not practical for a user.Roughly harmonized across Europe, minor differences as socket-outlets are permitted in Zone 1 etc. - RCD protection gets you to 0.04 s, so OK. A slightly more cautious approach, but there all the same.

I don't really see an issue for "wet" or "humid" as we either apply bonding, or use RCD in the UK.

Exterior locations are not classed as "wet" particularly in BS 7671. But your point is fair and definitely considered. RCD protection is used for outdoor socket-outlets and many items of outdoor equipment, so disconnection time is 0.04 s (Regulation 411.3.3). Larger circuits with Class I products, expect larger CPC and perhaps lower touch voltages ... and so on with that sort of thinking.

I'm surprised regarding exterior sockets, but this may come from the UK having a CPC since the WWII. I'd go on a limb and say the UK has not had many accidents involving outdoor equipment hence not being classed as a wet location, at least this would be my guess.

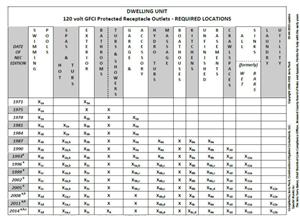

In the US where missing or no CPCs were common on metal tools, GFCIs were first required on outdoor receptacles before moving to bathrooms, garages, ect. The most injuries occured in outdoor locations.

gkenyon:ProMbrooke:Right, but what has me perplexed are the lack of tables in part 7. Exception being medical locations however this should apply to all kitchens, bathrooms, laundry areas, garages, unfinished basements, exterior sockets, pool circuits and the like- anywhere skin conductivity is lowered typically through moisture or large earthed surfaces.

Bonding and RCDs should not be the primary means to achieve protection in these areas. Rather a pyramid approach should be taken imo. Remote earth is impossible to avoid in all scenerios. RCDs have much higher failure rates compared to MCBs. Yet ADS remains the most simple, assured and reliable way of protecting life and property.Disconnection time may not be the answer, so that's why no tables.Where RCDs are specified, you're practically there already (0.04 s disconnection time OK for U0 230 V and your "Wet" table).

In terms of other locations, there is a need to take into account other issues, such as the clothing and footwear people are likely to be wearing etc - which change the touch voltages and disconnection times also. See IEC TR 60479-5:2007. IEC60479 : 2007 Effects of current on human beings and livestock –. Part 5:Touch voltage threshold values for physiological effects

I wish we knew their reasoning. IMO, 0.2 seconds is the answer in these locations should the RCD fail or where it can not be used reliably. BS7671 used to allow for skipping RCDs on circuits that can not tolerate inadvertent shutdowns.

ProMbrooke:gkenyon:ProMbrooke:Right, but what has me perplexed are the lack of tables in part 7. Exception being medical locations however this should apply to all kitchens, bathrooms, laundry areas, garages, unfinished basements, exterior sockets, pool circuits and the like- anywhere skin conductivity is lowered typically through moisture or large earthed surfaces.

Bonding and RCDs should not be the primary means to achieve protection in these areas. Rather a pyramid approach should be taken imo. Remote earth is impossible to avoid in all scenerios. RCDs have much higher failure rates compared to MCBs. Yet ADS remains the most simple, assured and reliable way of protecting life and property.Disconnection time may not be the answer, so that's why no tables.Where RCDs are specified, you're practically there already (0.04 s disconnection time OK for U0 230 V and your "Wet" table).

In terms of other locations, there is a need to take into account other issues, such as the clothing and footwear people are likely to be wearing etc - which change the touch voltages and disconnection times also. See IEC TR 60479-5:2007. IEC60479 : 2007 Effects of current on human beings and livestock –. Part 5:Touch voltage threshold values for physiological effects

I wish we knew their reasoning. IMO, 0.2 seconds is the answer in these locations should the RCD fail or where it can not be used reliably. BS7671 used to allow for skipping RCDs on circuits that can not tolerate inadvertent shutdowns.

We don't account for OCPD failure (e.g. mcb). However, nowhere in Section 701 (to use that as an example again) is RCD used alone - it always requires at least the condition of main bonding or supplementary local bonding (or both). In other cases, there may be other mitigating measures, such as footwear or circumstances, as I've pointed out.

And finally, don't forget that this is only where ADS is used (i.e. "Class I" or similar) - and even there, basic protection has to fail first. Where Class II or SELV/PELV is used, risks are even lower.

gkenyon:

That's interesting.

So, how should we approach TT systems?

Delayed RCD main in a plastic enclosure with 30ma sub-main RCD. However, clearing longer than 0.035 seconds of the main RCD may not be fast enough in areas of lowered skin conductivity.

In all honesty I'd like developed countries to move away from TT supplies. TT, TN-C-S and PME are simply a choice between cons in a world where DNOs do not want to provide more conductors than it takes to get the lights on. TN-S provides all the advantages of superior fault clearing given by TN-C-S, but without parallel earth currents or the risk of exposed parts becoming live should the neutral be lost.

In all honesty I'd like developed countries to move away from TT supplies. TT, TN-C-S and PME are simply a choice between cons in a world where DNOs do not want to provide more conductors than it takes to get the lights on. TN-S provides all the advantages of superior fault clearing given by TN-C-S, but without parallel earth currents or the risk of exposed parts becoming live should the neutral be lost.

The U.K. will not and can not change back to TN-S systems. It will be too complicated and costly. TN-C-S has its own issues.

I was recently at an outlying cottage in the countryside and was confirming the type of earthing provided. An occupier, an ex electrician, said that the supply was TT as the incoming supply cables had too high an earth fault loop impedance for a P.M.E. earthing system. We normally require a figure of about 0.35 Ohms for P.M.E. earthing. So, in this case the earhing was TT.

Also attached to the cottage was a stable block for horses, and TT earthing is very desirable where valuable four footed animals are concerned.

Z.

Zoomup:

In all honesty I'd like developed countries to move away from TT supplies. TT, TN-C-S and PME are simply a choice between cons in a world where DNOs do not want to provide more conductors than it takes to get the lights on. TN-S provides all the advantages of superior fault clearing given by TN-C-S, but without parallel earth currents or the risk of exposed parts becoming live should the neutral be lost.The U.K. will not and can not change back to TN-S systems. It will be too complicated and costly. TN-C-S has its own issues.

I was recently at an outlying cottage in the countryside and was confirming the type of earthing provided. An occupier, an ex electrician, said that the supply was TT as the incoming supply cables had too high an earth fault loop impedance for a P.M.E. earthing system. We normally require a figure of about 0.35 Ohms for P.M.E. earthing. So, in this case the earhing was TT.

Also attached to the cottage was a stable block for horses, and TT earthing is very desirable where valuable four footed animals are concerned.

Z.

Stray voltage is the byproduct of TN-C-S.

Any idea why the UK started off with TN-S but moved away from it?

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site