Is it me?

Chris Pearson:

whjohnson:

Most likely highlighting my ignorance here, but would a more obvious answer be that the earth terminal is just there to ‘park’ the cpc where a light fitting is changed but is using the existing wiring from a fitting which previously utilized it?

gkenyon:

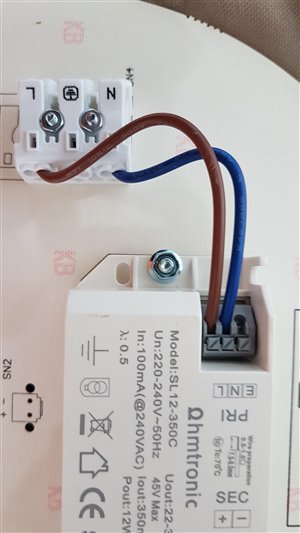

Reasonable assumption, but the IEC 60417-5017 symbol on the bottom-left of the driver is used where the equipment must be earthed.

Yes, but does it need to be earthed if it is a component of a Class II luminaire? That is why I asked about the markings on the complete product.

If the complete product is marked as Class II, then strictly not.

However, it does raise the question as to whether it's correct to put a Class I product inside a Class II product without earthing it.

For example, some safety isolating transformers require an earthed screen to achieve the full level of protection for SELV.

Without asking the question of the manufacturer of the “finished product” in which these drivers are incorporated, all you are left with is questions I'm afraid. As I said earlier, I wouldn't be happy and would either select another product, or obtain what I thought was a reasonable answer to my questions of the luminaire manufacturer.

As David and others have pointed out, there may well be nothing to worry about with the product. But at the end of the day, when an EICR is carried out, the inspector may well “FI” it, or even C2 it, so best to get it out of the way when you install it, as the installer will be seen as doing something wrong whatever the right of the matter is.

At least if you check with the manufacturer, and everything is OK, you can print a label saying “Class II product, checked with manufacturer on <date>. Do not Earth this product.” and stick it inside.

Chris Pearson:

whjohnson:

Most likely highlighting my ignorance here, but would a more obvious answer be that the earth terminal is just there to ‘park’ the cpc where a light fitting is changed but is using the existing wiring from a fitting which previously utilized it?

gkenyon:

Reasonable assumption, but the IEC 60417-5017 symbol on the bottom-left of the driver is used where the equipment must be earthed.

Yes, but does it need to be earthed if it is a component of a Class II luminaire? That is why I asked about the markings on the complete product.

If the complete product is marked as Class II, then strictly not.

However, it does raise the question as to whether it's correct to put a Class I product inside a Class II product without earthing it.

For example, some safety isolating transformers require an earthed screen to achieve the full level of protection for SELV.

Without asking the question of the manufacturer of the “finished product” in which these drivers are incorporated, all you are left with is questions I'm afraid. As I said earlier, I wouldn't be happy and would either select another product, or obtain what I thought was a reasonable answer to my questions of the luminaire manufacturer.

As David and others have pointed out, there may well be nothing to worry about with the product. But at the end of the day, when an EICR is carried out, the inspector may well “FI” it, or even C2 it, so best to get it out of the way when you install it, as the installer will be seen as doing something wrong whatever the right of the matter is.

At least if you check with the manufacturer, and everything is OK, you can print a label saying “Class II product, checked with manufacturer on <date>. Do not Earth this product.” and stick it inside.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site