Carrying on from a recent thread about the potential dangers of amateurs installing unvented undersink water heaters incorrectly….. Click on this

AncientMariner:

Then the next attending engineer after fixing the leak, asked if we were on a water meter? On the answer being yes, he asked where the expansion vessel was…… There wasn't one. Yet in the Installation manual it says that one is required.So why don't they fit one internally?

I take the point above about an expansion vessel in the heating circuit, but in this instance it presumably applies to the hot water side. I assume that water meters have some sort of one way valve?

I take the point above about an expansion vessel in the heating circuit, but in this instance it presumably applies to the hot water side. I assume that water meters have some sort of one way valve?

Good point - my mistake - I was indeed thinking of the heating circuit Doh.

- Andy.

Our CH boiler does have an internal expansion vsl for the heating circuit including the boiler side of the heat exchanger. The one we needed was for the cold feed.

It was an easy job to fit one once it came into a local plumbers merchant. But it was special order, since none of the merchants stocked them! This was only circa 2008, so not as if a combi boiler was a new idea. The last one I fitted I bought off eBay.

Clive

I have fitted a few for customers to resolve various odd problems.

https://www.bes.co.uk/mini-expansion-vessel-shock-arrestor-11355/

As regular readers on here know I like rules of thumb that allow a quick decision of ‘its OK’ or ‘it needs checking properly’.

I am not a plumber, but for a quick look and see, for the expansion vessel on the water heater, a good start is expecting an expansion volume of about 10% of the volume of the heated water, rounding up, rather than rounding down, to the nearest catalogue size vessel available if you are replacing.

This over estimates if the incoming cold supply pressure is low, and underestimates if it is already at the high limit.

So a 2 liter expansion tank ought to handle anything a 20 litre or less water heater can throw at it. Less volume may be OK, but it depends how much over-pressure can be absorbed by stretching things that do not really appreciate it, such as making taps drip and forcing water back up the street main.

Mike.

PS

for heating the text book formula is

Vexp = V_system *e/(1-p1/p2)

where p1/p2 is the ratio of the cold to hot pressure, perhaps 0.7- 0.8

a moments thought shows this also has to be an approximation.

relative to 25 °C

Expansion Factor ‘e’ | Temperature °C |

0.0324 | 85 |

0.0359 | 90 |

0.0396 | 95 |

0.0434 | 100 |

edit

(reference )

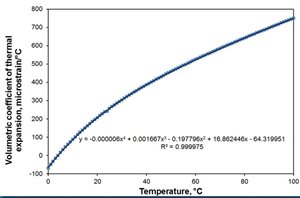

Actually to do the sums properly, note the expansion of water is highly non-linear with temperature, the rate (fraction of extra volume per degree rise is about 3 times higher approaching boiling, than it is at room temp, less as it gets colder, while it inverts at 4°C and stops shrinking starts to expand going colder, an effect that increases sharply as freezing commences)

In terms of volume change in litres per litre per °C,

Or for those who like graphs (or indeed arbitrary curve fitting with no good physical justification, other than ‘excel does it’ ) , - parts per million volume expansion per degree temperature rise up the side, vs temperature. (source)

You should get into routines when working, one of these is that when I am soldering pipes I open the taps.

Around twenty years ago I was replacing a kitchen in a care home and there was a hand wash basin with non-concussive self closing taps, twice without thinking I soldered the pipes and fittings and twice it leaked, then I secured the taps open by wrapping insulation tap around them to release the built up air pressure within the pipes whilst soldering.

Sparkingchip:

You should get into routines when working, one of these is that when I am soldering pipes I open the taps.Around twenty years ago I was replacing a kitchen in a care home and there was a hand wash basin with non-concussive self closing taps, twice without thinking I soldered the pipes and fittings and twice it leaked, then I secured the taps open by wrapping insulation tap around them to release the built up air pressure within the pipes whilst soldering.

Sparkingchip, thank you. That is a handy tip albeit not in a plumbing forum!

I would say that generally the taps (or radiators) would go on last, so not much of a problem.

I would say that generally the taps (or radiators) would go on last

Only for new installations/additions - for alterations they're likely to be there already.

My gotcha with soldered fittings was water dripping into the joint from a gate valve that didn't quite seal properly when fully off. I gather the old plumbers trick is to shove some white bread into the pipe before assembling/soldering - it blocks/absorbs any small trickle of water while the joint is made, but is readily broken down and forced out of taps when the main supply is back on. Probably not a good idea with some modern fittings with a filter on the inlet though…

- Andy.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site