Good evening everybody.

I've been cogitating on the fusing factor of 1362 fuses (specifically 13A fuses) and how this correlates with the protection of a 1.5mm2 flexible cable. As ever I am hoping you can shine a light!

The code of practice for the in service inspection and testing of equipment Table 15.6 states that for flexes to be protected by the fuse in a BS1363 plug there is no limit to their length providing that their csa's are as in table 15.6 which states a minimum flex size of 1.25mm when using a 13A fuse. I am minded that it is quite common site to see a multi-gang extension lead on sale using 1.5mm2 flex where there is obviously potential for overload given the unknown nature of what would be plugged into them (even though there will be a warning not to intentionally do so).

From the Beama guide:

2.5 The BS1362 Fuse

The UK uses a fused plug which must be fitted with a BS 1362 fuse. For domestic

installations the use of the BS 1363 plug and socket system and the fitting of a BS 1362 fuse

into a plug is a legal requirement under the UK Plug and Socket Safety Regulations, 1995.

With a correctly fused BS 1363 plug, the flexible cable connected to equipment is always fully

protected against the effects of overload or small overcurrents as follows:

3A fuse protects 0.5mm² cords

5A (6A) fuse protects 0.75mm² cords

13A fuse protects 1.25mm2 cords

Protection against excessive damage by a short circuit is still achieved even if the smaller

cord sizes are inadvertently protected by a 13A fuse. In addition, it has been accepted in the

UK that some marginal damage to small flexible cords is tolerable under short circuit

conditions, for example where a 0.22mm² cord is used with a 13A BS 1362 fuse.

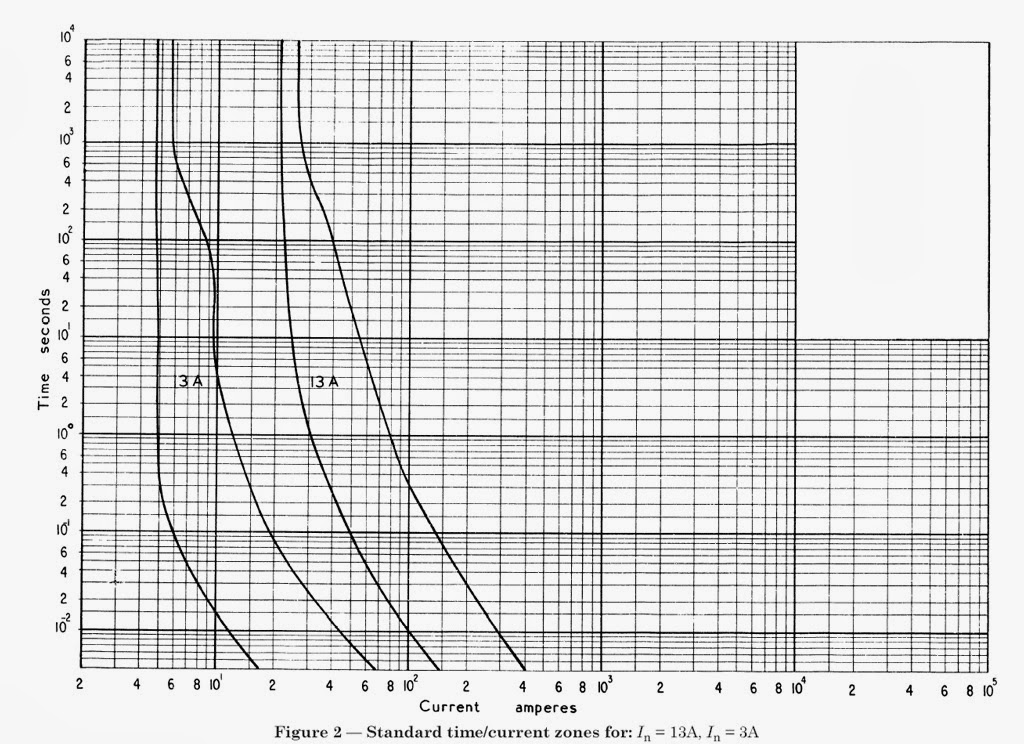

As far as I understand it the fusing factor of a 1362 fuse BS 1362 fuse is 1.9 (0.763) although in fairness I have seen lower fusing factors quoted (1.66?? which removes the particular problem I am wrestling with.)

Reference 4F3A a 1.5mm2 single phase AC flexible cable has a tabulated current carrying capacity of 16amps. 16x0.763 = 12.208 amps which is obviously less than the 13 amp rating of the fuse.

I find it quite common to see 13A 1362 fuses inline on 32A cooker circuits protecting 1.5mm2 flexes to ovens. Is this deemed acceptable even though the oven isn't strictly speaking a fixed load (fan motor etc.)?

Is there another factor at play here which I am missing? Or do I just have the wrong fusing factor!

Thanks for your help in advance.