Hi,

I have installed plenty of these devices, as well as their dimmer range.

https://shelly.cloud/products/shelly-1pm-smart-home-automation-relay/

What I am seeing however, is a number of people within online forums, installing these smart relays on ring mains. What they are doing is spurring from a ring, in 2.5mm and then switching this spur with the relay (without any form of fusing down, via means of an FCU).

I do not believe this is compliant, for the following reason:

- The relay is rated at 16A, and although it has overload protection, this is electronic and if the contact welds, the overload would not be broken by the relay itself.

If installed after a 13A fused connection unit, the device is not only protected by a 13A fuse (less than the contact rating) it is also then seen as some sort of appliance.

Is there anything else to add to this?

Would anyone here actually install these relays in-line with a ring main and if so, why/how does this comply with BS7671?

A few people have stated that the likes of Click Smart have a similar setup in a double socket:

https://click-smart.com/products/mode-smart-sockets

However these are covered by a product standard and not BS7671, so the application is very different.

Thoughts?

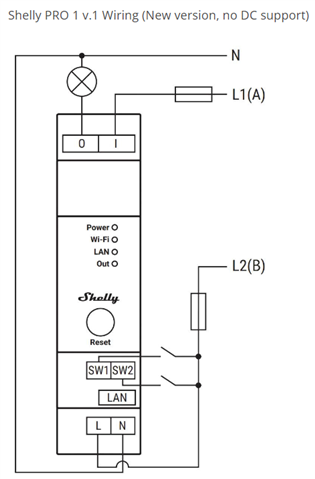

So it's the terminals on the bottom of the device. 5mm

So it's the terminals on the bottom of the device. 5mm