I have a temporary CU board setup for rewires etc. (CU, isolator, 25mm tails, earth block, socket outlets) that I want to make smaller (and also want to know theses answers anyway).

If I made a new temporary CU board setup with a mains isolator to 4mm T&E tails, to single module 32A RCBO, to 4mm T&E final circuit cable, to a socket outlet or two, do you think the 4mm tails would be compliant?

Overload protection - The 4mm tails (and reduction in CCC) are protected from overload by the 32A RCBO and design current of 32A of the socket circuit.

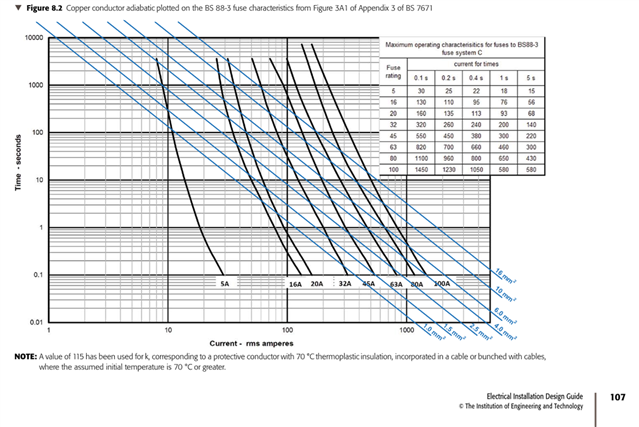

Fault protection - Lets say most common main fuse in domestic is 100A (worst case) BS 1361 / BS 88-3 which has a max Zs of 0.27 ohms to achieve a 5 second disconnection time for a distribution circuit on a TN system (0.14 ohms for 0.4 seconds). So if the Zs is <0.27 it's OK.

Main (tails) earth size would need to be the same as the line conductor (4mm) to comply with table 54.7.

Or use the adiabatic equation (amusing a Zs of less than 0.27 ohms):

S =

√ I2 x t

/ k

Where:

Zs = 0.27 ohms

I (fault current) = 851A (230 / 0.27)

t = 1s (850A on BS 88-3 time current graph)

k = 115 (70* thermoplastic) or 143 if separate cable

√ 851 x 851 x 1 = 851

851 / 115 = 7.4mm2

or 851 / 143 = 5.9mm2 (if separate cable)

So 4mm supply tails with 4mm earth using table 54.7 would be adequate? Am I missing anything? Thanks.