Hi All,

We came across this on a site last week and would be grateful for some clarification.

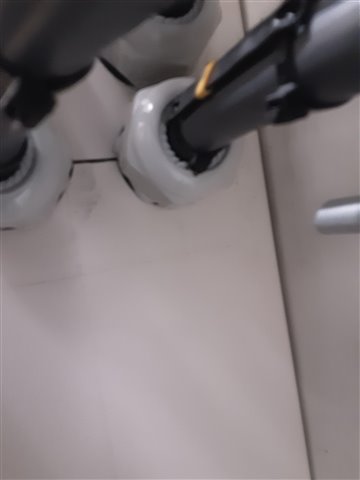

The panel board is supplied via single core double insulated 150mm conductors. As the picture shows, the cables enter through separate stuffing glands, but on closer inspection, the piece of metal in the centre has been slotted out so to be separate to the panel board itself.

As I have never seen it done this way before, could anyone confirm if this is compliant with 521.5.1 or if this could still cause an issue?

Regards

Mark