BS7671

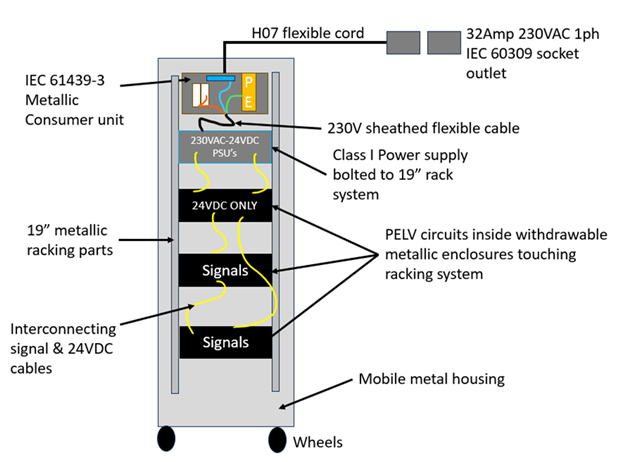

A mobile 19” racking enclosure containing a number of withdrawable LV class I items of equipment and other ELV measuring circuits contained within metal enclosures - the overall mobile racking unit is on wheels and floating from earth – however, the metal parts are only in contact with earth via the class I items located within it.

just considering protective systems and not EMC, I would instinctively say that the entire mobile unit and its mechanical elements eg vertical struts, doors and outer enclosure form part of the ‘installation’ . All conductive parts which could become live under single fault of one of the class I items, so therfore all conductive parts of the mobile unit ought to be bonded to its incoming supply earth terminal giving consideration to regulation 543.

But is it wrong to classify the racking system as exposed-conductive parts? Does the definition of exposed-conductive not extend to the racking it is bolted to?

Instead, does the racking qualify as extraneous-conductive parts which needs to comply with regulation 544 i.e. Bonded to the earthing terminal within the mobile enclosure with green/yellow not less than 6mm or half the CSA of the line conductors of the building’s incoming supply?

In summary, should I be bonding the racking parts via regulation 543, 544 or not bond at all?

Thanks