There seems to be a lot of emphasis on recording the highest value of PFC being less than the protective devises can safely handle, but little or no reference to when the pfc might be too low to operate the device in the prescribed time. In fact, most installation and inspection certificates simple note the device manufacturers maximum safe fault current, giving the electrician an excuse perhaps to not even measure the pfc!

I’m long retired but investigating a potentially serious electrical fire for a friend, though fortunately, this time, no fatalities as it was confined to a detached intake cabinet well away from the building. Which brings me to another point, the ESQC Regulations stress reporting an incident to the Secretary of State if any fatalities, but no such requirement if none (this time!). Sadly, a missed opportunity perhaps to reduce the risk of similar failures causing fatalities in future.

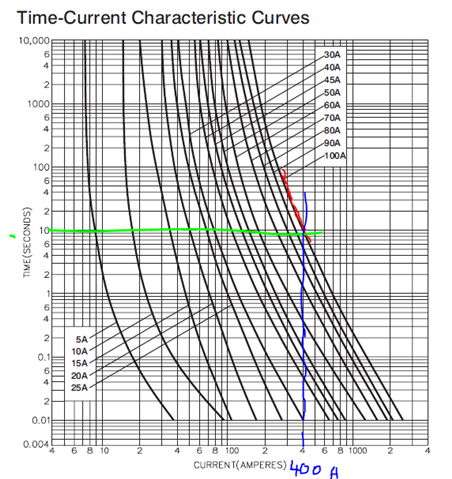

Anyway, for now, back to the pfc issue: In their case they had very recently had a 3 phase upgrade to their large property, with DNO 100amp cutout fuses (BS1361 or similar). The supply service cable serves several properties, with theirs being near the end of the supply service cable. Both the calculated pfc and measured value indicate around half the pfc required to operate the cutout fuses in the prescribed time, and in the event, persisted in the fault mode (apparently faulty meter or loose meter connection) for perhaps in excess of 15 minutes, further aiding the developing fire. Currently, their loads are all single phase and shared across the 3 phases, with ample capacity for future load additions.

So 2 questions if I may, one around the related ESQC regulations notification issue, and one about no obvious provision for recording a measured value of pfc on certificates, and no obvious requirement on the certificate to act accordingly when the measured pfc is too low.