Hi all,

A Client has recieved delivery of equipment incorporating a battery which is connected to a DC load by cabling. The cabling is protected by overcurrent protection in the equipment comprising aR fuses and contactors which are controlled by a proprietary arrangement with current monitoring, including what amounts to a definite time overcurrent function for overload protection.

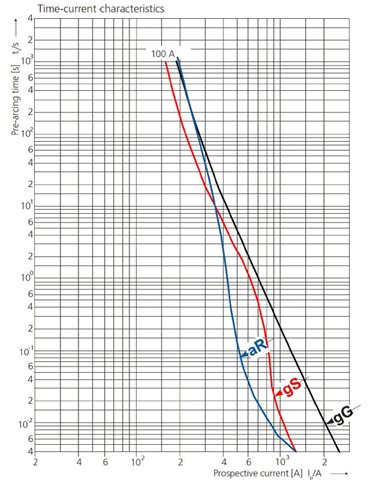

The concern is that the aR fuses are (by designation and design) not full-range, so provide fault protection only, while the contactors are only rated by the component OEM to break a certain overload current... and the fuse cut-off as for guaranteed performance is greater than the contactor break rating*. This leaves a small gap (circa 2% of the prospective fault current, or 10% of the contactor overload break rating) between the overload and fault protection functions where neither device is guaranteed to operate.

A side-note is that it is has not yet been confirmed to me that the overload trip is disabled above the contactor's break rating, so while the fuse will be available to act, up to double its rating the contactor might make the first attempt.

The equipment manufacturer has stated that they've carried out a test - details not provided - in which the fuse did operate in roughly half the I-t pre-arcing chart time (!) and the contactor survived (not sure if it operated) so everything's golden. The equipment does come with a third-party certificate of conformity to an appropriate IEC product standard. The standard does require the manufacturer to consider all external overcurrents and to declare any particular requirements for overload or fault protection, but from what I can tell the standard doesn't actually test for mid-range overcurrents, just small overloads and golden spanners.

My worry is that, irrespective of whether it's okay for the product/equpment standard, for the cable there may be a lack of compliance with BS7671 §430.3 and §435.2, insofar as there is a possibility that a high impedance fault, or an exceptionally bad day for the load controller, may give rise to overcurrent which neither overcurrent device is rated to break.

It would have been possible for the manufacturer to specify components with sufficient overlap (they exist), but retrospectively changing may not be easy not least as it might change its characteristics.

Questions:

- Am I right to pursue this gap in overcurrent protection for the cable or is the fact that its protection comes from within a piece of equipment to an IEC standard sufficient to meet the equivalency requirements of 533.1.1?

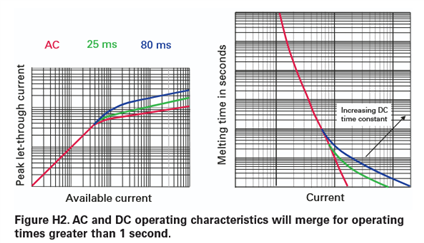

- What effect, in reality, might an attempt to break the over-overcurrent on this magnitude have on the contactor? Is it concievable that it might fail to break the current at all and/or fail disruptively, break it but need replacement afterwards, or is this one of those scenarios where safety tolerances mean that it will probably achieve the job just without as much margin as we'd like?

Jam

*The break rating is roughly 5x the nominal load rating