I am looking to specify a temporary mobile diesel generator and as such looking into the disconnection times and the maximum fault current provided by the genset.

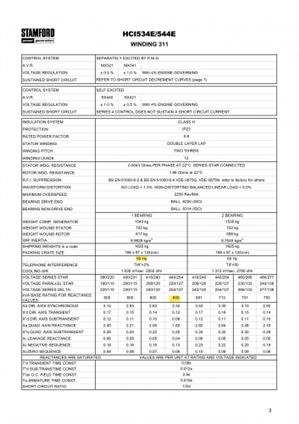

I have contacted a provider and got the specification of the alternator in their genset, images below of the fault current graph and the alternator per unit values.

I am looking into understanding what values to use. Am I correct in getting the sustained fault level and for an earth fault to apply the multiplication factor of 2.5 for sustained? I will make sure my disconnection times are less than the sustained maximum duration in order to not trip the generator breaker and loose all of the supply.

Alternator is 50Hz 415V