Hi

I am looking at a job where a supply to a replacement CT scanner has to be calculated.

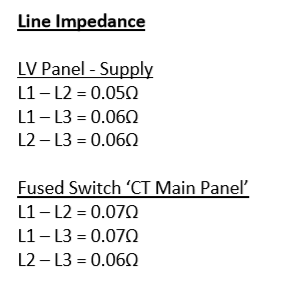

The current scanner is fed by a cable with line impedance 0.06 at source end of the sub panel that feeds it.

The new scanner must have a line impedance no more than 0.06 so basically I can't use the way on the current panel.

The client engineer has said to run from the intake and provide a cable calc to prove the line impedance is OK for the new scanner feed (this is D and B).

I am using AMTECH and was wondering if there was a way to output line impedance or if I need to show a calculation another way?

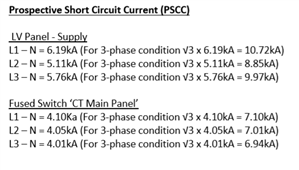

The client engaged a firm to do line impedance tests, and their report shows values measured between L1-L2, L2-L3 and L1-L3, but looks like they did testing at the sub panel and not at the intake.

This is basically like PSCC right? So I can get PSCC from AMTECH, divide by root 3 and work out impedance from there?

Am I on the right track? Assistance would be much appreciated.

Regards

Anisur