This is my first forum post and hopefully and interesting topic. I am looking for some advice on where to start!

Background:

- 4th floor apartment tear-out in the city of Baku, Azerbaijan in a very old Soviet-era building block with unknown amounts of modifications.

- 4 wire system (3-phase and neutral) entering and distributed throughout the building (no armoured cable / no separate earth).

- No enforced local regulations as the general wiring in the city is a free-for-all (I am told it should be to PUE 6 standard). I could share many examples but this is not the aim of this post!

- No building plans available from the council / no wiring / single-line diagrams available for the building or from the distributor.

- No option available for a reliable survey - Partly being that most of the local electricians think that an earth core is a waste of money!

- Basically the local distributor cannot be relied upon as can be seen by the photo example of the electrical panel closest to the apartment from the local government electrical company...

- I am an electrical engineer wanting to get my hands dirty with my own project compliant to the BS 7671 wiring regs. I will design the domestic electrical installation and will have it verified by an (UK) electrician / expat before proceeding and sourcing materials.

- Brand new domestic apartment electrical installation to BS 7671 18th Edition in which is in my control (full rewire, new consumer unit etc.). BS exceed the local regulations.

- Keep politics / what-should-be for the incoming panel out of the discussion, it is what it is and there is not much I can do except wait decades for regulations and enforcements to catch up!

- Provide the safest solution to protect my family without running away from the building / country.

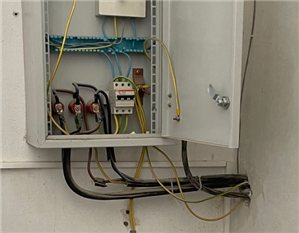

Closest Panel to my Apartment:

- Ok lets cut to the chase - this may just be the worst panel that you have ever seen however I cannot modify it as it is owned by the local government electrical company. It gets no points for compliance to any regulation (maybe 1 for being metal only!). I unfortunately has to live with this monstrosity until the building is knocked down in the future (and this is one of the newer / better panels in the building believe it or not…1 of 3 panels up to the apartment).

Queries:

- Can I assume that the incoming supply is a TN-C-S (and I know this is the distributors responsibility…) i.e. connect the MET and neutral together before the consumer panel? I know we should never assume so what is the best way to test? I am trying to source a Megger. My concern is that this could bypass some protection elsewhere in the building although it appears to have only overcurrent protection (fuses).

- Should I have a dedicated earth run from the incoming of the building (from the neutral bar) up to the apartment consumer unit instead? My concern is that there my be a potential difference between the neutral and the earth at the apartment which could require 2P RCBOs throughout. Yes there should not be a potential difference however there is a lot of twisted wiring (junction boxes are a luxury…) and poor looking connections as well as all the apartment neutrals connected together in the block.

- A third option would be to have an earth pit installed in the car park and run the dedicated earth to the MET in the apartment although 2P RCBOs may still be required.

Any assistance is greatly appreciated including verification / testing methods before I dive into the design of the consumer unit. Thank you in advance,

Chris