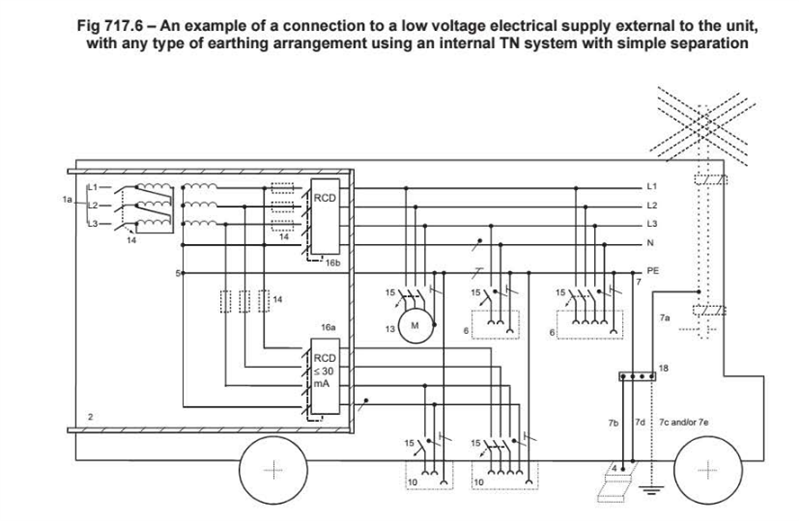

We have recently modified transportable units to the configuration described in Figure 17.6 of BS 7671. These units are connected at various third party locations around the country, with different types of supply systems.

IET Guidance Note 7: 18th: Amendment 2: 14.4.2 TN system states A PME earthing facility shall not be used as the means of earthing for mobile and transportable units falling within the scope of this Chapter, except where: (a) the installation is continuously under the supervision of an electrically instructed person competent in such work; skilled or (b) the suitability and effectiveness of the means of earthing has been confirmed before the connection is made; or (c) the unit is located within, or outdoors on an upper storey or roof of, a building or structure containing the electrical installation which supplies the unit.

The note goes onto state: There are many installations in premises that are TN-C-S in form and ordinary persons will be most unlikely to understand and fulfil the requirements set out in (a) and (b) above. It is therefore recommended that the arrangements of Figure 14.6 are followed wherever an ordinary person is required to use, operate or connect a unit to a supply with unknown or uncertain earthing arrangement.

As we have understood the unit to include the electrical installation within it, does this mean the cable used to supply the unit (up to the primary side of the isolating transformer) could be connected to a PME supply provided the earthing system at the supply point provide by the third party is suitable and effective (Zs is acceptable and the RCD trips)?