Hello,

I have a question regarding a specific topic.

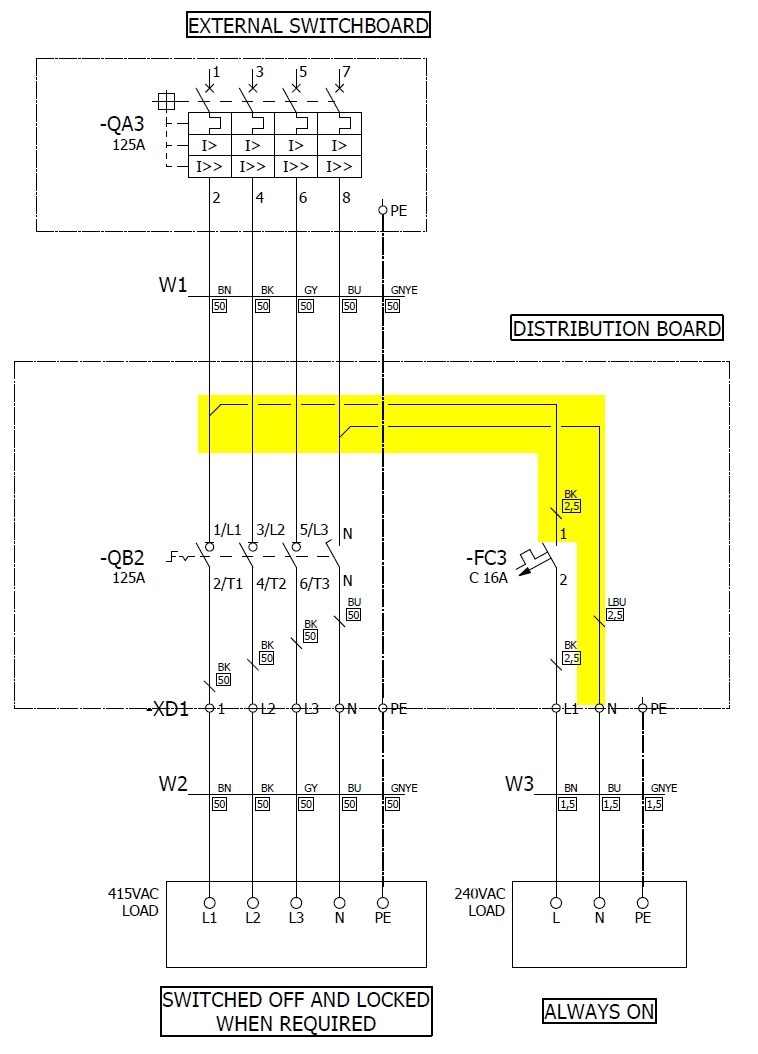

I need to create an isolation box with 2 specific goals:

1 - To ensure a specific load is off and locked

2 - To have a secondary supply for a secondary load ensuring it is always on

With that in mind, I have considered the solution as per example attached.

My question is related to the connection between the main isolator of the Distribution Board (-QB2) and the Auxiliary breaker (-FC3).

The protection to the Distribution Board is ensured by the breaker upstream at the External Switchboard (-QA3) which ensures both cables W1, W2 and the 3 phase load are protected.

The connections to the smaller breaker have a much reduced CSA than the main supply cable W1 (2,5 vs 50 mm2).

The breaker upstream will not protect the smaller CSA cable but that is the case on many situations when busbars are not used. The auxiliary breaker (-FC3) will protect the downstream cable W3 and the load because the rating is suitable from that point downwards. But not upstream this breaker. You can say it is unprotected.

I think this is still allowed in BS7671 on a specific article 434.2 Position of devices for protection against fault current (434.2.1) where some conditions need to be met including a limitation of length.

That is my question.

Am I interpreting this correctly?

The 3 phase load is a standard load not covered under the article 433.3.3.

Any feedback will be much appreciated.

Thank you

Kind regards