I had an email this morning from the IET telling me that a Draft for Public Consultation has been published for Amendment 3 to BS 7671.

Details here electrical.theiet.org/.../

JP

I had an email this morning from the IET telling me that a Draft for Public Consultation has been published for Amendment 3 to BS 7671.

Details here electrical.theiet.org/.../

JP

closed

Yes it would normally interrupt at the next half cycle.

Also it's been tested for an inductive load fault at 0.7 pf so the thyristor will be able to handle substantial back EMF too.

However if you've got an inverter in a fault state that starts feeding DC, or a line-commutated inverter that depends on its load to get back to zero crossing then you might have a problem. A 1kVA line-communtated inverter would need to dump upto around 10J before it can zero cross.

That said, if an installation has a line-communtated inverter it would become apparent quite quickly that it's not compatible with the RCBO. Ultimately we're supposed press the T button regularly. My main worry with this ammendment is that it's going to trigger a lot of inappropriate C2s from people interpreting a lack of protection and therefore potentially dangerous when in reality the risk is in many circumstances there's still fault and overload protection so it would tend to be a C3.

I'm not sure how the proposed wording can be changed to address that - the GN2&GN6 are the place for that commentary. But we know very well that whenever there's a national departure of this kind there's a guarantee that people will over-react.

Having seen no end of incompetent board changes to address inappropriate C2s on plastic boards that ought to have been C3 - I'm sceptical. At the same time there's some very sensible points here which Graham Kenyon is rightly highlighting and I agree with him that they should be addressed.

It's very difficult to choose wording which is objective and there's nothing Graham and his colleagues on JPEL/64 can do about people willfully misusing the regs - they have to assume people are competent even though clearly not everyone is.

It's very difficult to choose wording which is objective and there's nothing Graham and his colleagues on JPEL/64 can do about people willfully misusing the regs - they have to assume people are competent even though clearly not everyone is.

Yes, but when you have BEAMA giving strongly worded advice;

Along with what looks like an emergency amendment to 7671 being rushed through with the only focus being on the bidirectional issue, one can hardly fault lads inspecting installations from jumping to the conclusion that this is an important safety matter worthy of a code 2!

Nor indeed, is it reasonable to contend that lads at this level would have the technical understanding necessary to make informed decisions other than what is embedded in the messaging.

So one would hope ESF or the like will be quick of the mark to guide the troops in this case.

Yes, but when you have BEAMA giving strongly worded advice;

Thats what worries me, and what I find curious.

If this is the serious issue that report suggests then why aren't their any case studies? Surely there's countless examples of exactly this? I was involved on a policy side with the requirements for non-combustable DBs - which was very sensible and has undoubtedly saved lives - but it was based in good evidence and the LFB were excellent in their provision of data and case studies.

My interest in this particular ammendment is because I am responsible for a product used right in this part of a circuit - and we have to withstand OVCIV due to the transients. I'm of the school of being candid about hazards so that as engineers we can work them.

It looks like someone has identified a problem. But there's no candour about the scope of it. It might well affect bidirectional RCCBs which depend on SCPDs. It might well affect adjustable speed drives but there's nothing in the BEAMA note about that or the scope this ammendment.

If an unidirectional RCBO has spent the last 10 years on a G99 compliant PV installation and had the T button pressed under reverse load countless times then in view of the fact that the inverter has loss of mains protection and the RCBO must accept a 6kA fault through a heavily inductive load anyway then whilst I completely agree its a C3 I can't agree that it's a potentially dangerous installation.

If BEAMA have information that would disabuse anyone who feels that way then their being very closed about it.

I'm worried that we've got an ammendment without a good treatment of the problem. And a 10 page report of which 9 pages are covers, contents, summary and diagrams for anyone who doesn't know what a consumer unit looks like isn't a treatment of the problem.

It seems AMD3 is trying to mitigate tip of the larger problem. The problem of "unidirectional" and "bidirectional" RC devices stems from the way electronics are designed on the secondary winding inside. But the problem is not just the design but the fact that the functionality of modern RCD/RCBO in UK relies on electronics at all. As many of you may already be aware - this type of design was disallowed on mainland continent and most of RCBOs sold nowadays in UK are illegal to use in EU because the electronics will not function without neutral (eg. in the event of PEN fault). The device that's supposed to be part of secondary protection and fire protection will do absolutely nothing if the fault starts by burning through neutral. Just a few years ago just about any RCBO with electronic release would have a flylead connected to MET ensuring the device was still functioning without neutral under fault conditions, but with time even that failsafe was withdrawn from most of the designs.

So - don't add unidirectional and bidirectional malarky to the regs - just ban shoddy electronic designs from UK markets all together before it becomes larger issue. Most of the world already did.

As many of you may already be aware - this type of design was disallowed on mainland continent and most of RCBOs sold nowadays in UK are illegal to use in EU because the electronics will not function without neutral (eg. in the event of PEN fault). The device that's supposed to be part of secondary protection and fire protection will do absolutely nothing if the fault starts by burning through neutral.

Is this correct? I'm sceptical because the terms in BS EN 61009-1 relating to voltage dependant operation aren't BS national departures.

The overcurrent functions of an RCBO are not dependent upon voltage - they are essentially an MCB in these respects.

The RCD characteristic however is. And you're correct that there's no guarantee this will work if the L-N voltage drops below 0.8 nominal.

But it would need multiple faults for this to become a hazard. For example a PEN fault is a fault condition so if this was to coincide with a secondary fault that was unable to clear then yes that would be immediately dangerous.

I can see some justification in domestic where the risk of existing faults is sufficiently high - hence the elevated requirements for AP in the first place. But then the advantage of AP by 30mA RCDs [as opposed to e.g. the traditional supplementary bonding approach] is that a problem raises its head and the occupants hopefully ring their electrician about an annoying RCBO.

FEs are a bit of a pain. I've always wondered why they don't put a supercapacitor or something in - but would have its own problems.

Some also argue that we should have upfront PEN protection - I'm not convinced but I think smart meters should report undervoltage to the DNO.

Ultimately protective devices are there for fault conditions not dodgy wiring - which aren't the same thing.

but I think smart meters should report undervoltage to the DNO.

I think that would be a good idea ... overvoltage too.

The device that's supposed to be part of secondary protection and fire protection will do absolutely nothing if the fault starts by burning through neutral.

I'm not following your thinking here. Protective devices generally only provide protection to downstream conductors, not upstream - if the downstream N burns out, then the device will still have a supply N and can function normally. If the supply N burns out, I agree the device won't trip - but then tripping wouldn't help disconnect the fault - and unless there's a simultaneous fault downstream, there would be no need to disconnect anyway.

- Andy.

-

If the supply N burns out, I agree the device won't trip - but then tripping wouldn't help disconnect the fault - and unless there's a simultaneous fault downstream, there would be no need to disconnect anyway.

I think there's an issue with TT systems if a voltage dependant RCD was providing fault protection.

Personal opinion is that 30mA RCDs/RCBOs are for additional protection and should only be used for TT fault protection where no additional protection is required - I think a TT board should be backed with a type S for fault protection. The regs don't spell it out but I think the clue is in the name *additional* protection - i.e. supplementary to standard fault&overcurrent protection.

S type RCDs are almost universally independent of voltage because of how they work internally although that might change if type S&B combined become a thing.

I certainly think Martin raises interesting points. If you get two electical engineers to discuss PEN faults you'll get four opinions.

- which now there can't be as the only load on the mechanism side of the open contacts is the RCD electronics etc themselves - and that current (if the diagram is correct) should be returning through the toroid.

Unless the test button remains pressed in which case the imbalance remains and the thyristor (or I guess it could be a triac in some designs) is fired again?

Unless the test button remains pressed in which case the imbalance remains and the thyristor (or I guess it could be a triac in some designs) is fired again?

Of the units I've pulled apart I think every one of them has 2x 2.7k 1206 resistors in series [giving 5.4k and therefore 42mA]. A 1206 resistor is typically rated to 250mW but some go up to 1W.

So for continuous pressing the resistors are grossly undersized - at 230V this would dissapate 4.9W in each <= 1W resistor! So they clearly depend on the breaker opening in order to get away with this. I have a feeling these are 0.75W's with a rating to 2.5x rated voltage for short term overload so they can take 4.68W for 5s which is still what Sir Alex Ferguson would call squeeky bum time.

Should note however that manufacturers usually take one side of the test button to the metalwork on the solenoid. For many this means that the button is between Lin and Nout - for others it's between Lout and Nout depending on if the solenoid is before or after the contactor. One thing i've noticed is that the diagram on the side of the devices is only a functional description and typically bears little resemblance to internal operation.

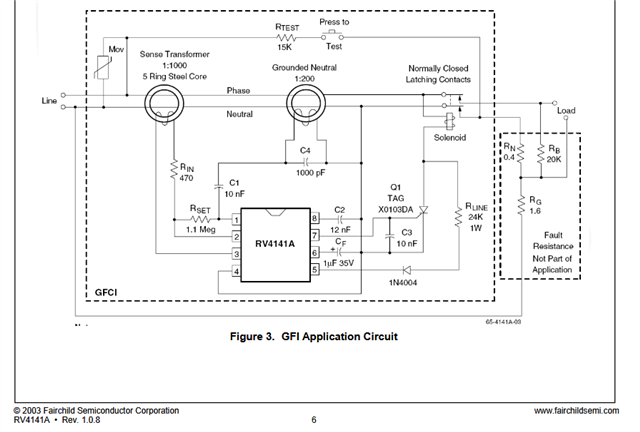

What I've found particularly interesting is that most of these devices use one of a handfull of GFCI controller's IC such as the popular but end of life RV4141 from Fairchild Semiconductor [now ON Semiconductor]. I mention this because on all of the application notes I've seen from ON & TI who dominate this market is that they all have the electronics on the incoming side - whereas RCBO manufacturers prefer to put the electronics on the outgoing side. The image below is from the bottom of pg 6 to the RV4141A datasheet. [this example circuit probably only meets Type AC and not A due to core saturation combined with the fact it only works on one half cycle, and it's configured for UL 943]

Edit: one consequence that has just occured to me - If you lock off and RCBO following safe isolation then someone comes along and presses the T button - this would on some DP devices connect Nout to Lin via 5.4k of resistance. This would come as a very nasty surprise to a person working on the isolated circuit.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site