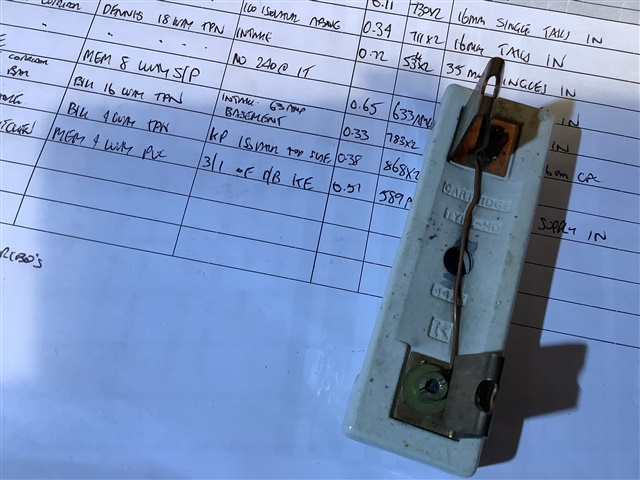

Just want to check my calculations and conclusions are correct.

(been meaning to do this for a while)

Checking if a 2.5/1.0mm cpc is acceptable on a 32A ring final for an EICR.

In this example looking at data for MK 32 A MCB MK data sheet

In the graphs I am assuming the horizontal is PSCC/PFC. In my example I have a PFC of 700A, therefore I2T = about 5000 A/sec

Energy withstand for 1.0cpc K2S2 = 115*115 * 1.0 = 13,225

I2t needs to be less than K2S2

5000 < 13,225 therefore I am ok.

If I look at the graph and find I2t of 13,000 it looks like I am ok for pscc/pfc up to about 3K, bit difficult to read with linear graduation on a log scale.

In reality the B type actually switches in 10msec with 5 * rated current rather than the 100msec typically used in calculations.