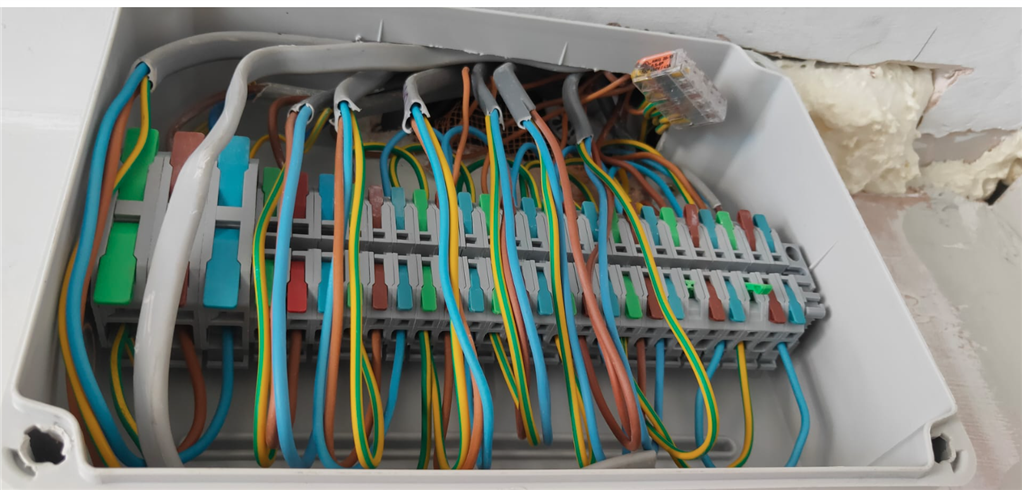

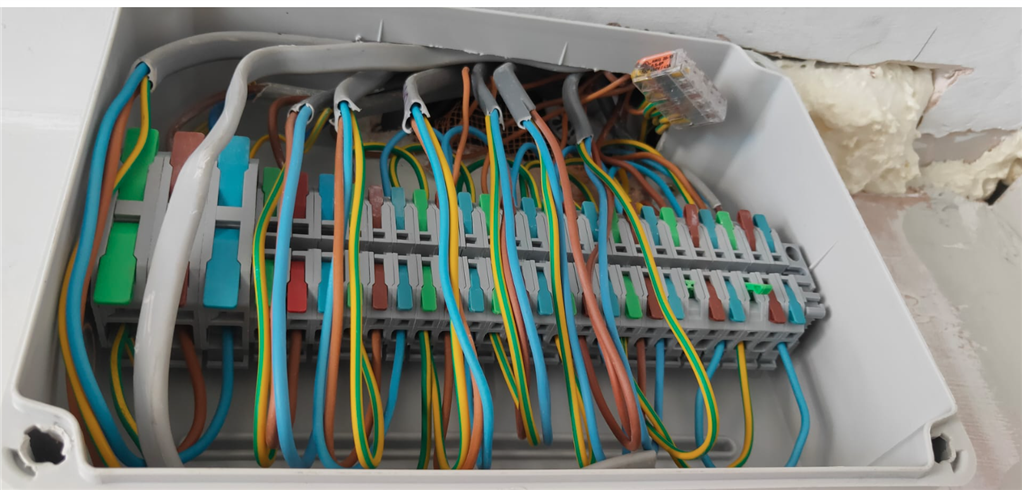

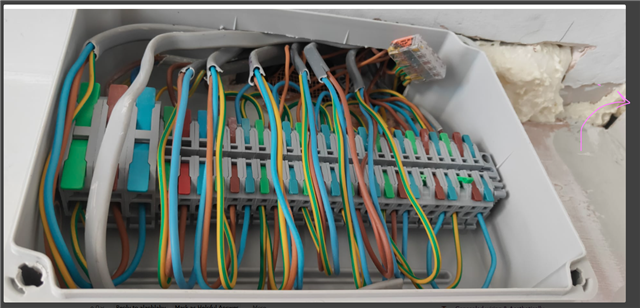

This junction box has been installed by my builder's electrical worker, the void above the box is the ceiling space on ground floor

is this acceptable for residential installation?

This junction box has been installed by my builder's electrical worker, the void above the box is the ceiling space on ground floor

is this acceptable for residential installation?

There should be a minor works certificate (example - though 'circuit details' would require duplicetion as here there are several circuits) or the equivalent information presented another way.

There may not be a full set of tests as per a full EIC, but the new work should have some sort of earth continuity tests, either dead tests before connection or a Zs afterwards, and I'd expect to see RCD trip times verified. If the EICR was done after the new work, that's OK as the test coverage and reported test results are similar (model forms), but usually it is done before, to avoid surprises when hooking on. It is true to say that there is quite wide variation in the degree to which this is taken seriously - especially the extrapolation from sampling only part of the installation rather than the whole of it.

Mike

well, yes, certainly in domestic and near domestic installations the utilization factor is very low - the installation has that many circuits for convenience of isolation for servicing, not because there is that much load. The same error occurs when folk total the breaker ratings to estimate maximum demand, when most of the day the whole house could probably be fed by a single 13A plug !

In your shoes I'd feel no great guilt about extending in the same cross-section, unless something was really undersize (like a 4mm2 shower circuit) or looking distressed, or the route was in some way unable to cool - perhaps in a boiler room ceiling, or a run in thick insulation, but I might consider a flatter trunking option or maybe a few parallel runs of the thinner stuff, so the wires are spread out sideways, and also it looks less ugly on corners.

Let's see what others say about it though

M.

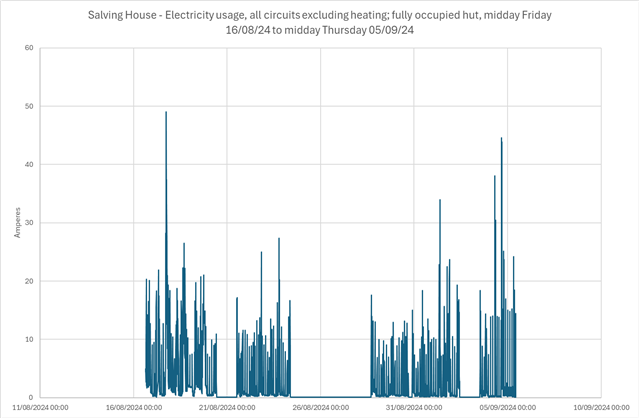

Mike raises the issue of cable ratings and grouping factors which resonated with me because I'm currently working on a similar project involving the replacement / relocation of a consumer unit in a commercial building.

The current installation has the final circuit cables (twenty off T+E) tightly bunched together where they come through the ceiling and into the consumer unit (see photo). My intention is to route the existing cables into a steel enclosure with DIN rail mounted connectors, similar to that in the original post, then run singles inside a metre (approx.) of steel trunking to a new consumer unit mounted in a more accessible location.

If I apply the appropriate grouping factors, even after accounting for the lightly loaded circuits such as lighting and fire alarm panel, I arrive at some quite hefty cable sizes (25 mm2 for the showers, 16 mm2 for the cookers and ring finals etc.) which make my intended approach somewhat impractical. However, the entire installation is protected by the supplier's cut out fuse which has a rating of no more than 100 A, and which has not, to my knowledge, ever blown. Furthermore, I have logged the total demand over a typical couple of weeks and the current rarely exceeds 20 A and then only for brief periods, presumably when the showers and or cookers are in simultaneous use. There is no evidence of overheating in the existing bunched cables. I also note that the aggregate cross sectional area of the existing cables supplying the cookers and showers alone (two of each) already exceed 25 mm2 (It = 101 A).

I intend, therefore, to install singles with the same CSA as the existing cables; I would nevertheless be interested to hear other peoples opinions.

Kind regards

Geoff

So, the box is mounted on some boxing that runs front to back on the house, just the other side of the wall to the right is a steel, the plasterboard installed here was pink, I'm not sure and doubt that the plasterboard here is pink, definitely not double

it is a normal standard house, I'm not aware of fire zones.

I think the works fits as minor works as it was all modification of existing circuits, should I expect a minor works certificate? I think they are planning to provide EICR only

Is the ceiling that has been cut a fire break between 2 independent zones ? If so then a hole that size might compromise it.

Or to check this, is it 2 layers of plasterboard or it is the pink stuff that is fire rated?

Normally in a 'standard' house with 2 floors and one set of stairs, upstairs and downstairs are one zone, But situations like granny flats or a third habitable floor can change this.

It's not exactly first class neat work but it may not be a wiring regs or building regs fail.

There are some builders sadly who seem to specialize in bumbling along near the shallow end of the acceptable.

Perhaps if you have not seen it already ask for the paperwork - there should be new installation (or perhaps just minor works if its a small extension) certs and the some test results. That often results in a rash of activity, and it not being available would be a regs fail, albeit a very common one.

Mike.

Thanks all for your input.

This is not the result of any equipment being moved, it is a collection of new lighting circuits in an extension that have been grouped together for connection in a central point. This box has been presented supplementary to all the hidden connections in the ceiling that were used to modify the existing circuits.

There is a lid to the box and access from above would be through the floor, so not an issue.

There are some unsheathed cables outside the box, I haven't yet been closer to pull them out, there is also a collection of PE in the Wago strip, I'm guessing he ran out of terminal space. I'm pretty sure one of these is clamped around the earth sleeve

The quality of the installation is just naff, including chewed out hole and spray foam, but I recognise that people have different levels and abilities of this. I'm not sure why the cables had to move from the original hole but I'm bored of asking my builder about cosmetic issues now.

My concern is the gaping hole, my understanding is that it is not appropriate for electrical installation and that the cable entries should be sealed to prevent the spread of fire.

Good spot!

The lever seems to be broken in the triplet left of it, but cpc and N: where is the line?

(Presumably, there was a CU up against the ceiling at one time.)

Is somebody going to push down that half-open green lever?

Personally I don't like the large hole at the top - far too easy for dust, dirt, grit and all the other detritus that seems to magically appear in floor voids, to fall down into the innards - and I suspect lever terminals will be less tolerant of that than traditional screw ones.But technically it's not an accessible top surface so no automatic IP4X requirement. You could argue about it not being suitable for the conditions, but it's a vague requirement rather than something black and white you can point to - any there are many other much worse examples out there that seem to prove themselves adequate enough. There's also a hint of unsheathed cables outside of the enclosure, but that might be the camera angle...

- Andy.

looks neat enough would suggest grommet strip and fire sealing the entrance to the enclosure. Labelling the enclosure and cables for future maintenance would be a nice touch.

We're about to take you to the IET registration website. Don't worry though, you'll be sent straight back to the community after completing the registration.

Continue to the IET registration site