Hello,

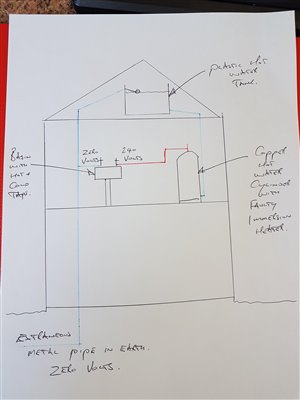

Thinking about a domestic dwelling with main bonding to incoming water and gas pipes (even though most are plastic nowadays); all the electrical circuits within the dwelling are protected by RCDs; the only extraneous conductive parts to the bathroom being copper water pipes and copper central heating pipes... Why would the copper pipes need to be main bonded one to another close to the bathroom (in an accessible place for testing, like in an airing cupboard)?

Designing an installation which uses the cold water pipe in place of a main bonding cable (having a cross-sectional area which is greater, after all), why would any of the other three pipes need to be main bonded to that cold water pipe, when all of the pipes connect at the boiler any how?! Yes, if you were to cut all of the pipes and to replace them with plastic pipes then you risk introducing an electrical potential into the bathroom should a fault occur, but wouldn’t anyone doing that plumbing be obliged to consider this risk at that time?

Otherwise, there is no point considering the use of copper pipes to replace main bonding cables. In which case, it would be necessary to bond the pipes one to another just outside the bathroom and run the cable all of the way back to the consumer unit.

I must excuse myself for being indolent and not referring directly to the wiring regulations, which is from where these ideas stem.