We have a Insulation Resistance measurement unit from Hioki - ST5520.

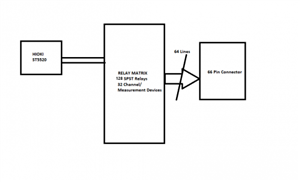

We are using this to measure multiple devices controlled through a relay matrix as shown in the figure. The positive and negative terminals of the ST5520 is multiplexed through the relay matrix to the 64 pins of the connector. There are 7 pcb's each containing 20 relays.

The individual board testing from ST5520 to the connector is giving a open condition result with a high value of insulation resistance of 9.90Gohm @1000V, when there is no load at the connector output, it is left open.

But the when the whole system is wired and tested with the 7 pcb's(all 32 channels), the value fluctuates and starts with a value from 100Mohm and eventually reaches open condition value.

Is there a problem with this process of multiple channel testing? or this is the expected behaviour? the open condition value(9.90Gohm@1000V) is maintained once it reaches this value and further tests result in this same value.

Once the system is left OFF for a period of a day, then the testing is resumed again, the same behaviour of starting from 100Mohm to open condition value repeats. Is this to be expected or i am understanding/ doing something wrong?

Any help with this is much appreciated. Thanks in advance.